Flexible feeder systems are machines that rely on regular maintenance and upkeep to ensure they can continue to work efficiently. Without regular maintenance, they can become unreliable, inefficient and, in some cases, dangerous.

In this article, we will discuss the importance of regular maintenance in flexible feeder systems, the benefits of doing so, and some common maintenance tasks that should be performed. We will also provide some frequently asked questions (FAQs) at the end to help you better understand the importance of regular maintenance.

What Is a Flexible Feeder System?

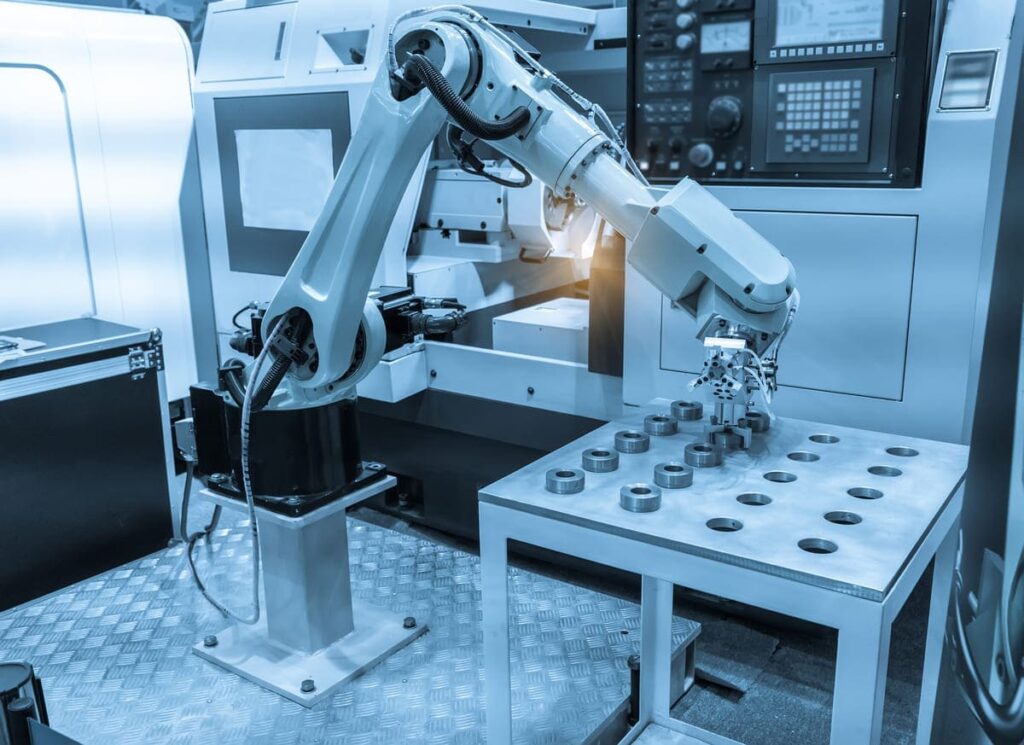

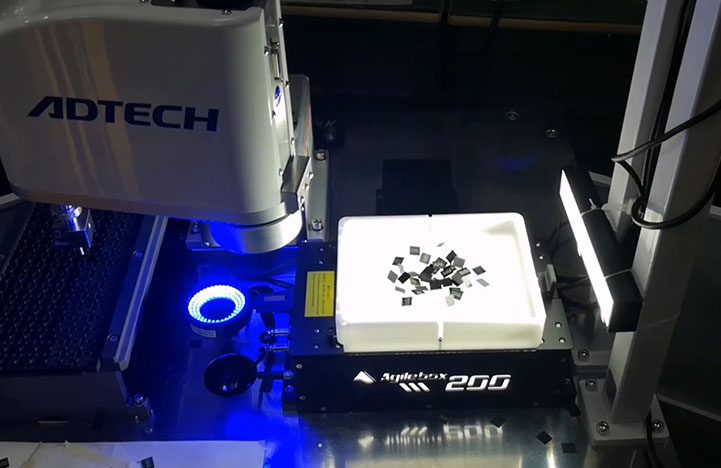

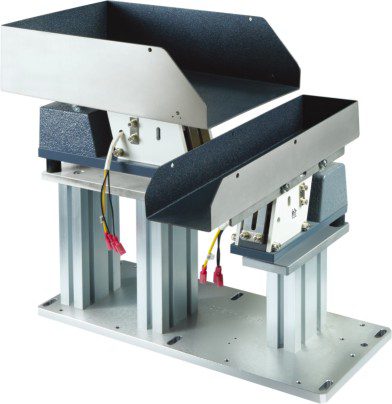

A flexible feeder system is a type of machine that is used to feed or transport materials in a manufacturing or industrial setting. These machines can be used to move a variety of materials, such as raw materials, components, finished products, and more.

They are typically composed of two main components: a conveyor system and a storage system. The conveyor system is responsible for transporting the materials from one area to another, while the storage system is responsible for storing the materials until they are needed.

Why Is It Important to Perform Regular Maintenance on a Flexible Feeder System?

Regular maintenance on a flexible feeder system is essential to keep it running efficiently and safely. Without regular maintenance, the system can experience a number of issues, such as increased wear and tear, decreased efficiency, and even potential safety hazards. Here are some of the key benefits of performing regular maintenance on a flexible feeder system.

Improved Performance

Regular maintenance can help to improve the overall performance of a flexible feeder system. This is because it ensures that all the parts of the system are in good working order and any problems are caught and fixed before they can cause any major issues. This can help to reduce downtime, increase efficiency, and improve the accuracy of the system.

Reduced Wear and Tear

Regular maintenance can also help to reduce wear and tear on the system. This is because it allows for any worn or damaged parts to be replaced before they cause any major problems. This can help to extend the life of the system and reduce the need for costly repairs or replacements.

Increased Safety

Regular maintenance can also help to improve the safety of the system. This is because it can help to identify and fix any potential safety hazards before they can cause any serious harm. This is especially important in industrial settings, where the system may be used to transport heavy or hazardous materials.

What Are Some Common Maintenance Tasks on a Flexible Feeder System?

There are a number of different maintenance tasks that should be performed on a flexible feeder system. Here are some of the most common:

Inspection

Inspecting the system is one of the most important maintenance tasks. This should be done regularly to ensure that all parts of the system are in good working order and any potential problems are identified and addressed.

Lubrication

Lubrication is also important to ensure that the system is running smoothly. This should be done regularly to ensure that all parts are well lubricated and not experiencing too much friction.

Adjustment

Adjustments should also be made to the system on a regular basis. This is important to ensure that the system is running optimally and to make any necessary adjustments to keep it working efficiently.

Cleaning

Cleaning should also be done regularly to ensure that the system is free from any debris or contaminants that could potentially cause problems. This includes cleaning any moving parts and any other parts that may be exposed to dust or debris.

FAQs

Q: How often should I perform maintenance on my flexible feeder system?

A: The frequency of maintenance will depend on the type of system and the environment in which it is used. In general, it is recommended that maintenance be performed at least once per month to ensure that the system is running optimally and any potential problems are identified and addressed.

Q: What types of maintenance tasks should I perform on my system?

A: The types of maintenance tasks will depend on the type of system and the environment in which it is used. In general, some of the most common tasks include inspection, lubrication, adjustment, and cleaning.

Q: What are the benefits of performing regular maintenance on my flexible feeder system?

A: The benefits of performing regular maintenance include improved performance, reduced wear and tear, and increased safety. Regular maintenance can help to ensure that the system is running efficiently, safely, and that any potential problems are identified and addressed before they can cause any major issues.

Conclusion

In conclusion, it is essential to perform regular maintenance on a flexible feeder system to ensure it is running optimally and safely. Regular maintenance can help to improve performance, reduce wear and tear, and increase safety. Common maintenance tasks include inspection, lubrication, adjustment, and cleaning. By performing these tasks on a regular basis, you can ensure that your system is running efficiently and safely.