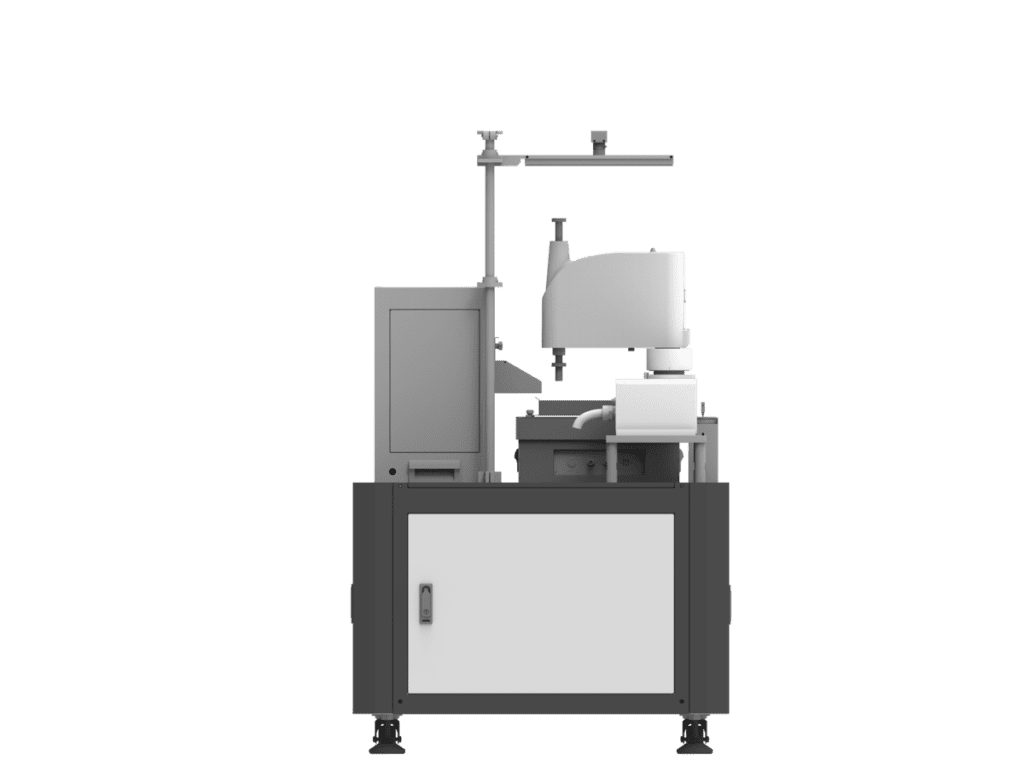

Flexible feeder systems are becoming increasingly popular in high-speed production lines due to their ability to handle parts of varying sizes and shapes quickly and efficiently.

In this article, we will discuss the benefits and challenges of using flexible feeder systems for high-speed production lines and provide tips for optimizing their performance.

Benefits of Using Flexible Feeder Systems for High-Speed Production Lines

Speed

Flexible feeder systems can operate at high speeds, allowing for increased production output and reduced downtime. The use of advanced control systems can further optimize the feeding process, ensuring that the feeder system operates at maximum speed without sacrificing accuracy or reliability.

Versatility

Flexible feeder systems can handle a wide range of part sizes and shapes, making them ideal for high-speed production lines that require versatility in their feeding processes. The use of customizable feeding mechanisms can further enhance the system’s versatility, allowing it to handle even more complex geometries and part variations.

Accuracy

Despite their high speed, flexible feeder systems can maintain high levels of accuracy in part placement. The use of vision technology and advanced control systems can ensure that parts are placed correctly and quickly, reducing the risk of errors or misplacements.

Efficiency

The use of flexible feeder systems can significantly increase efficiency in a high-speed production line. The speed, versatility, and accuracy of these systems can reduce downtime and increase production output, ultimately improving the overall efficiency of the manufacturing process.

Challenges of Using Flexible Feeder Systems for High-Speed Production Lines

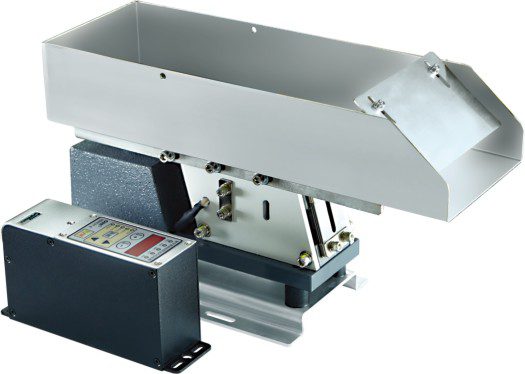

Part Jamming

Part jamming can be a significant challenge in high-speed production lines, particularly when dealing with small or delicate parts. If parts become jammed, it can cause downtime and damage to the feeder system.

Solution: The use of specialized feeding mechanisms, such as vacuum or air jets, can help prevent parts jamming. These mechanisms can be adjusted to the size and shape of the parts being fed, ensuring smooth operation. Regular cleaning and maintenance of the feeder system can also help prevent debris buildup that can cause jamming.

Feeder Synchronization

When using multiple feeder systems in a high-speed production line, synchronization can become a challenge. If one feeder system is not in sync with the others, it can cause delays and stoppages in the manufacturing process.

Solution: The use of advanced control systems can help ensure feeder synchronization. These systems can communicate with each other and adjust feeder speeds and timing to ensure smooth operation.

Part Orientation

Ensuring proper part orientation is essential for accurate and efficient feeding in a high-speed production line. However, when dealing with complex geometries or fragile parts, part orientation can become a significant challenge.

Solution: The use of vision systems can be effective in ensuring proper part orientation. Vision systems can identify the orientation of parts and communicate that information to the feeder system, allowing for accurate placement.