In today’s ever-changing world of production, manufacturers are faced with the challenge of keeping up with the ever-evolving demands of the market. High-mix, low-volume production is becoming increasingly popular, as it allows manufacturers to produce a variety of products in small quantities, while still maintaining high-quality standards.

As such, it is important for manufacturers to have the right equipment in place to allow for rapid, efficient production. This is where flexible feeder systems come into play.

Flexible feeder systems are designed to be easily adjustable, allowing for quick and accurate adjustments to accommodate a wide range of products. These systems are capable of handling a wide variety of components, including small, delicate parts, as well as larger and heavier components.

They also offer a high degree of automation, as they can be programmed to handle a wide range of production tasks. This eliminates the need for manual intervention, which can save time and reduce labor costs.

Flexible feeder systems are ideal for high-mix, low-volume production, as they can quickly and easily be adapted to handle a wide range of products. This is especially true for those in the automotive, electronics, and medical device industries, as these industries often require the production of a wide range of products in small quantities.

Flexible feeder systems allow for the rapid and efficient production of these products, allowing for shorter lead times and greater flexibility.

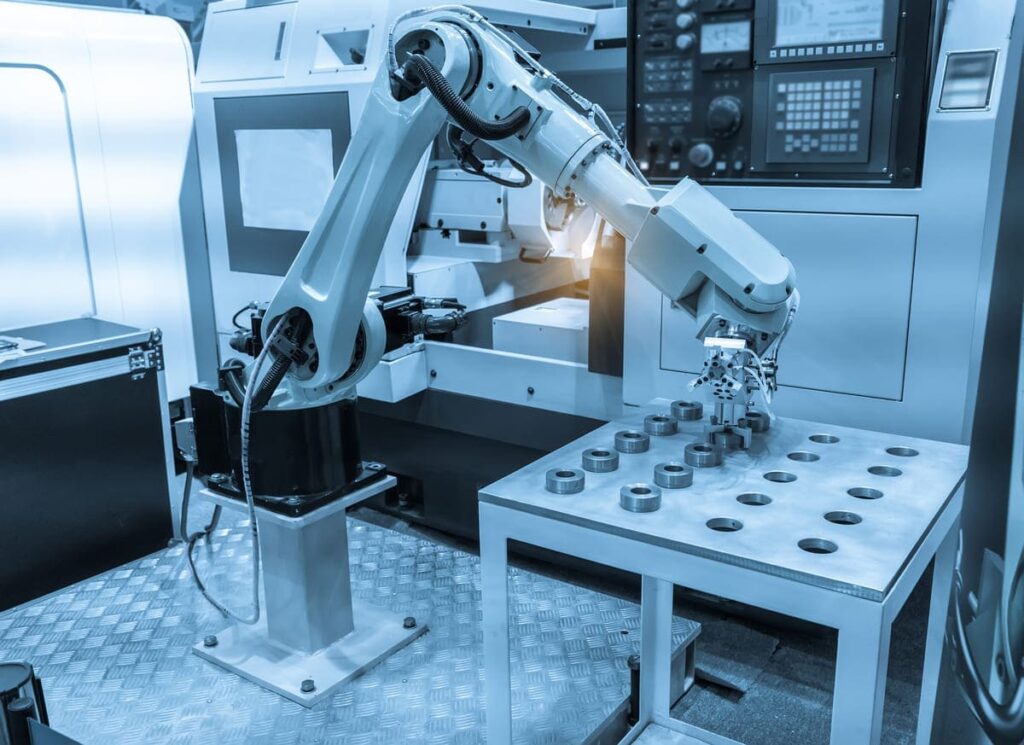

Flexible feeder systems are also well-suited for high-mix, low-volume production as they can be easily integrated with other machines and systems. For example, they can be combined with robotic and automated systems to increase efficiency and accuracy.

This allows for faster production and greater control over the production process. Additionally, flexible feeder systems can be used in conjunction with other machines, such as 3D printers, to produce custom parts and components. This allows manufacturers to quickly and easily produce complex components with a high degree of accuracy.

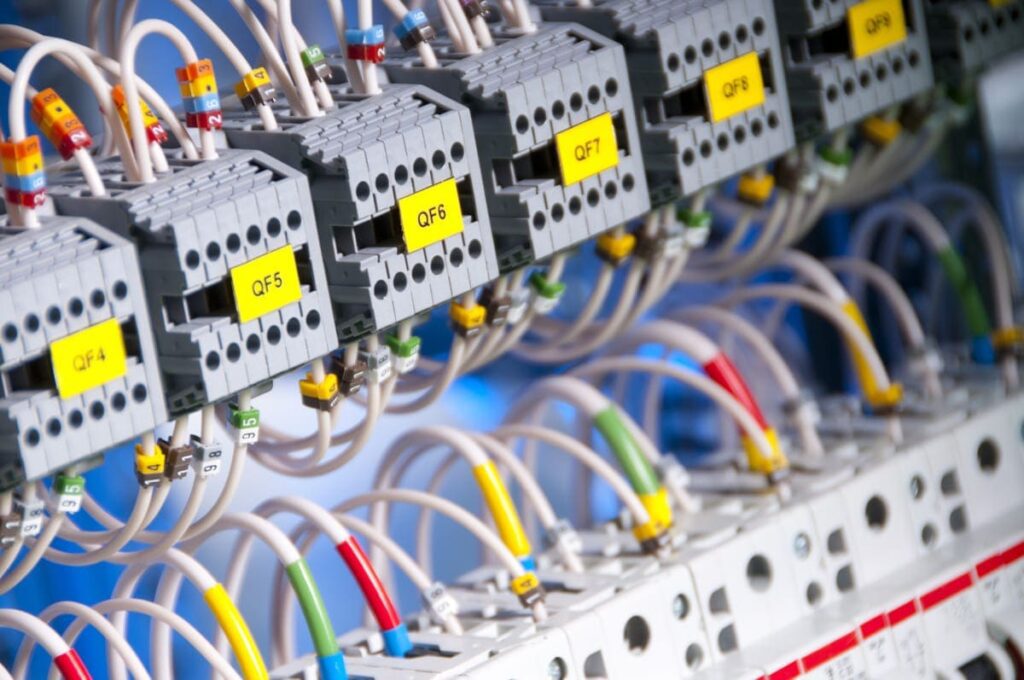

Flexible feeder systems are also beneficial for manufacturers because they are easy to maintain and operate. They are designed to be user-friendly, allowing for quick and easy setup and operation.

Additionally, they are designed with safety in mind, with features such as guard rails and safety interlocks to protect operators from potential hazards. This makes them an ideal choice for those looking for a safe and efficient production solution.

In conclusion, flexible feeder systems are an ideal solution for high-mix, low-volume production. They offer a high degree of automation, allowing for rapid and efficient production of a wide range of products.

Additionally, they are easy to maintain and operate, making them a safe and convenient choice for manufacturers. As such, they are an ideal choice for those looking for a reliable and cost-effective production solution.

FAQs

Q: What is a flexible feeder system?

A: A flexible feeder system is a type of production system that is designed to be easily adjustable, allowing for quick and accurate adjustments to accommodate a wide range of products. It is often used in high-mix, low-volume production, as it allows for rapid and efficient production of multiple products in small quantities.

Q: What industries can benefit from using flexible feeder systems?

A: Flexible feeder systems are ideal for those in the automotive, electronics, and medical device industries, as these industries often require the production of a wide range of products in small quantities. Additionally, they are well-suited for any industry that requires the production of complex components in small quantities.

Q: What are the benefits of using a flexible feeder system?

A: There are many benefits to using a flexible feeder system, including improved efficiency, increased accuracy, shorter lead times, and greater control over the production process. Additionally, they are user-friendly and designed with safety in mind, making them a safe and convenient choice for manufacturers.

Q: How can flexible feeder systems be integrated with other machines and systems?

A: Flexible feeder systems can be easily integrated with other machines and systems, such as robotic and automated systems and 3D printers. This allows for faster production and greater control over the production process, as well as the ability to produce custom parts and components.