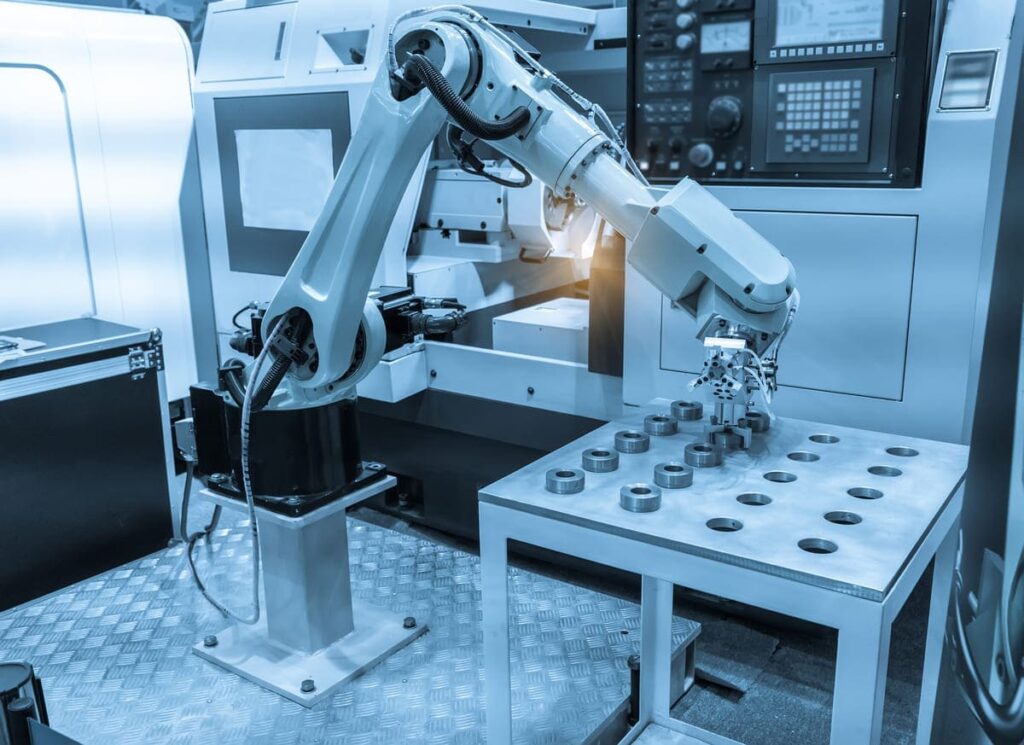

Flexible feeders are an essential component of many manufacturing operations. They offer a wide range of benefits, including increased productivity, versatility, and ease of use.

However, like any other equipment, flexible feeder systems require regular maintenance to ensure they function optimally.

In this article, we will discuss some tips for maintaining your flexible feeder system to ensure it operates efficiently and effectively.

Regular Cleaning

One of the most important aspects of maintaining your flexible feeder system is regular cleaning. Over time, dust, debris, and other contaminants can accumulate in the feeder bowl, which can cause parts to get stuck or become damaged.

To prevent this, it is important to clean the feeder bowl and other components regularly. This can be done using a soft brush or compressed air to remove any debris or contaminants.

It is also important to use a cleaning solution that is appropriate for the type of material used in the feeder bowl.

Inspecting for Wear and Tear

Another important aspect of maintaining your flexible feeder system is inspecting the components for signs of wear and tear. Over time, the feeder bowl, feeder base, and other components can become damaged, which can reduce their lifespan and cause issues with the feeding process.

To prevent this, it is important to inspect the components regularly for signs of wear and tear. This can be done visually, by looking for any signs of cracks, corrosion, or other damage. If any damage is found, it is important to replace the component immediately.

Lubrication

Proper lubrication is essential for the smooth operation of your flexible feeder system. Lubrication helps to reduce friction and wear on the components, which can help to extend their lifespan and prevent issues with the feeding process.

To ensure proper lubrication, it is important to use a lubricant that is appropriate for the type of material used in the feeder bowl. It is also important to apply the lubricant regularly, following the manufacturer’s recommendations.

Proper Storage

When your flexible feeder system is not in use, it is important to store it properly to prevent damage and ensure its longevity. This includes keeping the feeder bowl and other components clean and dry and storing them in a cool, dry location.

It is also important to properly disassemble the feeder system before storing it and to pack the components in a way that prevents them from becoming damaged during transport or storage.

FAQs

Q: How often should I clean my flexible feeder system?

A: It is recommended that you clean your flexible feeder system after every use to prevent debris and contaminants from accumulating in the feeder bowl.

Q: What type of cleaning solution should I use to clean my feeder bowl?

A: The type of cleaning solution you use will depend on the type of material used in the feeder bowl. It is important to use a cleaning solution that is appropriate for the material to prevent damage.

Q: How often should I inspect my feeder components for signs of wear and tear?

A: It is recommended that you inspect your feeder components at least once a week to ensure they are functioning properly and to identify any signs of wear and tear.

Q: What type of lubricant should I use for my flexible feeder system?

A: The type of lubricant you use will depend on the type of material used in the feeder bowl. It is important to use a lubricant that is appropriate for the material to ensure proper lubrication.

Q: How should I store my flexible feeder system when it is not in use?

A: It is important to store your flexible feeder system in a cool, dry location, and to properly disassemble the feeder system before storing it to prevent damage.