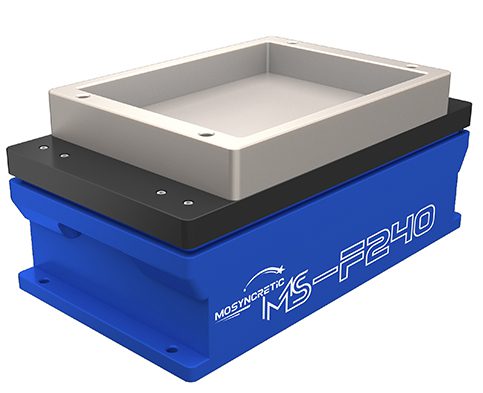

The internal structure of the flexible vibration plate includes a vibrator set on the frame, a vibration plate set on the output end of the vibrator, and a bearing platform set on the vibration plate, the vibrator includes a motor, a support rail, a spring plate, and a universal support column, the motor has a stator and a kinetic, the stator of the motor is fixed on the frame, the support rail is set on the circumference of the motor, the kinetic of the motor is set on the support rail and slides along the support rail, the spring plate is fixedly connected to the kinetic of the motor and the frame, the universal support column is set on the kinetic of the motor, the vibration plate is set on the universal support column. The spring plate is fixedly connected with the motor’s movable sub and the frame, the universal support column is set on the motor’s movable sub, and the vibration plate is set on the universal support column. The working principle of the flexible vibration plate is that by setting four vibrators distributed in the four corners of the bearing platform, the motor is connected to the vibration plate through the universal support column, four motors are installed in the four corners of the vibration plate, constituting a four-vibration source three-axis vibration platform to realize the turning and horizontal displacement action of the parts on the bearing platform, which can better realize the turning and moving of the parts with good vibration effect. The bottom surface of the bearing platform is a quadrilateral structure, and the number of vibrators is four, so that the vibration effect of the bearing platform, parts in the bearing platform flip and horizontal movement for good effect, can be faster to achieve the attitude of the parts change, the bottom surface of the bearing platform made of light-transmitting material, and the lower side of the bearing platform is equipped with led backlight so that the camera device shooting high definition, identification and pick up High efficiency.

Automating Mobile Phone Camera Cover Handling with Flexible Feeders

we explore the innovative application of flexible feeders in the automation process for mobile phone camera covers. These small, delicate components present unique challenges for