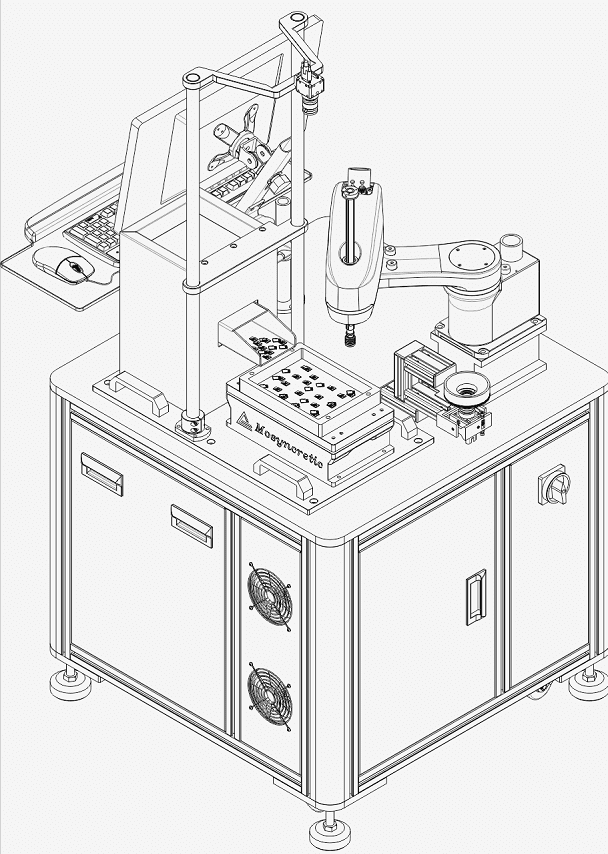

Flexible feeders are becoming increasingly popular in the manufacturing industry. They are devices used to transport, sort, and orientate parts in a production line.

They have the ability to handle different types of parts and can be adjusted to work with various sizes and shapes.

They are an essential part of the manufacturing process as they help to speed up production and increase efficiency. manufacturing industry.

There are different types of flexible feeders available in the market today, each with its unique features and benefits.

In this article, we will explore the different types of flexible feeders and compare them to help you make an informed decision when selecting one for your manufacturing needs.

Vibratory Feeders

Vibratory feeders are the most common type of flexible feeder. They work by moving parts in a circular motion, which causes them to separate from each other. Vibratory feeders are very versatile and can be used to handle parts of different shapes and sizes.

Vibratory feeders are usually used in conjunction with other equipment, such as hoppers or conveyors. They are also ideal for handling fragile or delicate parts as they can be adjusted to handle parts gently.

Centrifugal Feeders

Centrifugal feeders are another type of flexible feeder that uses a spinning disc to sort and orientate parts. They are ideal for handling parts that are small, lightweight, and have simple shapes. Centrifugal feeders can handle parts at high speeds and are ideal for use in high-speed production lines.

One of the main advantages of centrifugal feeders is their ability to handle parts that are difficult to orientate using other types of feeders. They can also be adjusted to handle parts with varying shapes and sizes.

FlexiBowl® Feeders

FlexiBowl® feeders are a newer type of flexible feeder that uses a flexible bowl instead of a rigid one. The bowl is made of silicone and can be adjusted to handle parts of different shapes and sizes.

FlexiBowl® feeders are ideal for handling fragile or delicate parts as they can be adjusted to handle parts gently.

One of the main advantages of FlexiBowl® feeders is their ability to handle parts that are difficult to orientate using other types of feeders. They can also handle parts with complex shapes and sizes, making them ideal for use in a variety of production lines.

Gravity Feeders

Gravity feeders are a type of flexible feeder that uses the force of gravity to transport and orientate parts. They are ideal for handling parts that are small, lightweight, and have simple shapes.

Gravity feeders are usually used in conjunction with other equipment, such as hoppers or conveyors.

One of the main advantages of gravity feeders is their simplicity. They do not require any moving parts, which makes them very reliable and easy to maintain. They are also very cost-effective and ideal for use in low-speed production lines.

Step Feeders

Step feeders are a type of flexible feeder that uses steps or platforms to transport and orientate parts. They are ideal for handling parts that are small, lightweight, and have simple shapes. Step feeders can be adjusted to handle parts of different shapes and sizes.

One of the main advantages of step feeders is their ability to handle parts at a consistent speed. They are also very reliable and easy to maintain, making them ideal for use in high-speed production lines.

To help you make an informed decision when selecting a flexible feeder for your manufacturing needs, we have compared the different types of flexible feeders based on their features and benefits. manufacturing needs, we have compared the different types of Flexible Feeder | Features and Benefits

Vibratory Feeders | Very versatile and can handle parts of different shapes and sizes.

Flexible feeders are an important part of industrial automation systems, which are used to feed parts and components to machines or assembly lines.

There are several different types of flexible feeders available in the market. Here is a comparison of some of the most common types of flexible feeders:

Vibratory feeders: Vibratory feeders are the most widely used type of flexible feeders. They use vibrations to move parts and are suitable for feeding small to medium-sized parts.

Vibratory feeders can be customized to feed parts of different shapes and sizes. However, they are not suitable for fragile parts or parts with sharp edges.

FlexiBowl feeders: FlexiBowl feeders use a flexible bowl with a rotating disc to sort and feed parts.

They are suitable for feeding a wide range of parts, including fragile and odd-shaped parts. FlexiBowl feeders are also easy to retool and can be used to feed multiple types of parts.

Vision-based feeders: Vision-based feeders use cameras and image processing software to identify and sort parts.

They are suitable for feeding complex and high-precision parts. However, they are also more expensive and require more setup time than other types of flexible feeders.

Step feeders: Step feeders use a series of steps or ridges to sort and feed parts.

They are suitable for feeding larger and heavier parts that are difficult to handle with other types of feeders. Step feeders can also be used to feed parts with irregular shapes or sizes.

Vacuum feeders: Vacuum feeders use suction to pick up and move parts. They are suitable for feeding delicate and thin parts, such as electronic components.

Vacuum feeders can also be used to handle parts with irregular shapes or sizes. However, they are not suitable for heavy or bulky parts.

Overall, the choice of flexible feeder depends on the specific needs of the application. Factors such as part size, shape, weight, fragility, and production volume should be taken into consideration when selecting a flexible feeder.