Choosing the right flexible feeder size for your factory depends on a variety of factors. It is important to consider the type and volume of raw materials that will be stored in the feeders, as well as how quickly they need to be processed. If you are handling bulk materials, then larger feeders are recommended since they can accommodate more material at once while keeping production running smoothly. For smaller parts, or those with a high throughput rate, smaller flexible feeders may be appropriate. Additionally, you should consider how easy it is to access the feeding system for maintenance and cleaning; this also affects what size is best for your needs. Finally, review any safety regulations in place related to production machinery—these may dictate certain restrictions on specific sizes of flexible feeders that have been deemed safe for use in industrial environments.

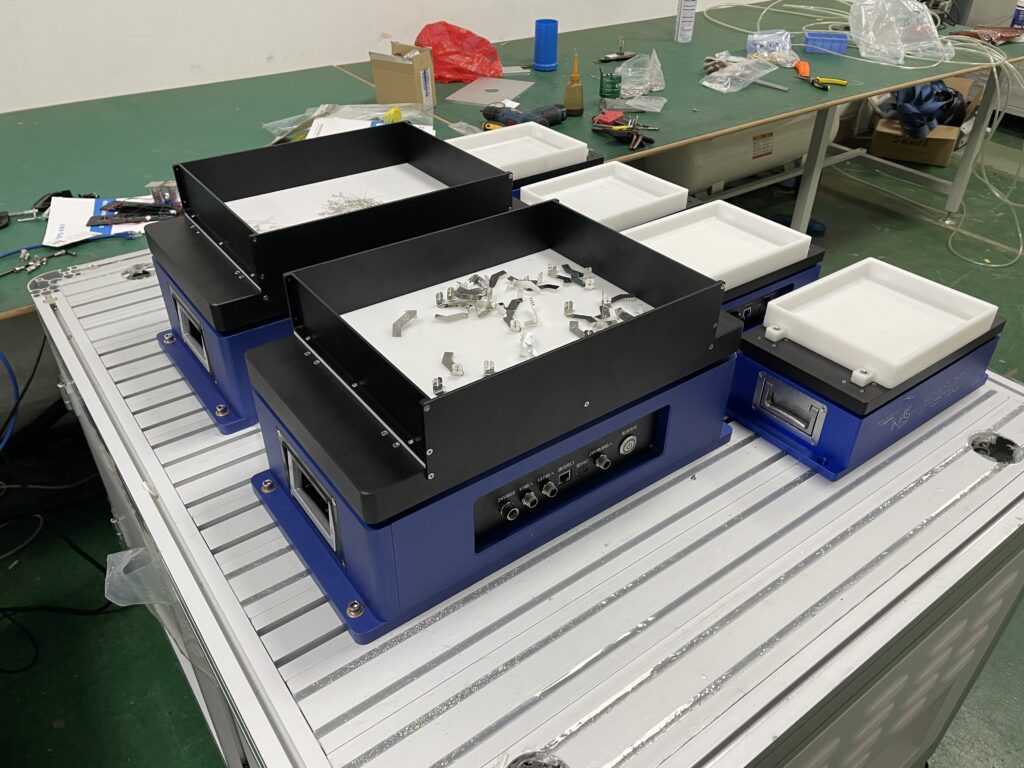

Automating Mobile Phone Camera Cover Handling with Flexible Feeders

we explore the innovative application of flexible feeders in the automation process for mobile phone camera covers. These small, delicate components present unique challenges for