Flexible Feeding System

Flexible feeding system is a kind of automatic production line workstation which adopts advanced automation equipment and control system and can adapt to different production needs and process requirements.

- High production flexibility

- High degree of automation

- High production efficiency

- High product accuracy

- High reliability

- Less human intervention

Free design of the whole structure

Design the whole machine size according to your working environment.

Structure Introduction

The flexible feeder system structure consists of a hardware structure, CCD camera, flexible feeder, Hopper, Robot, Ending-tools.

Robotic

Supports all brands and types of robot integration.

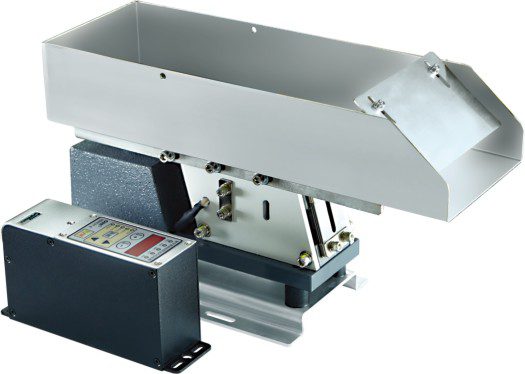

1 of 5 HopperHopper

Customizable with different capacity hopper.

2 of 5 VisionVision

Multi-pixel model selection available.

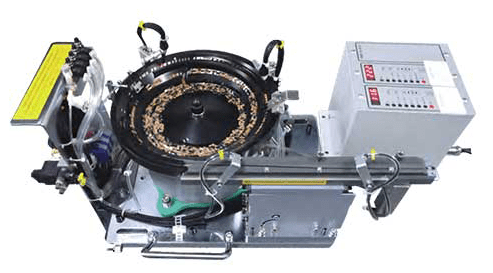

3 of 5 Flexible FeederFlexible Feeder

Multi-size plate sizes available.

4 of 5 Hardware StructureHardware Structure

Custom sizes available, shield option.

5 of 5Application

Tape and Reel

Assembly Automation

Sorting Automation

CNC Loading

Medical Applications

Advantages of Flexible Feeder

Flexible feeders are advanced automation solutions used in various industries to improve the efficiency and speed of production lines.

Flexible feeders can handle a variety of part sizes, shapes, and materials, which makes it easier and quicker to switch between different products on the same production line, reducing downtime and increasing overall efficiency.

By automating the feeding process and eliminating manual handling, flexible feeders can increase productivity, allowing for higher throughput and reduced labor costs.

Flexible feeders can improve product quality by reducing the risk of human error during the feeding process. They can also be integrated with vision systems and other quality control measures to ensure accurate and consistent part placement.

Flexible feeders can be customized to suit specific production requirements, enabling manufacturers to optimize their processes for maximum efficiency and output.

As production requirements change, flexible feeders can be easily adapted or reconfigured to handle new parts or increased volumes, making them a future-proof solution for growing businesses.

As many industries face labor shortages, flexible feeders can help fill the gap by automating tasks that were previously performed manually. This allows companies to maintain or even increase production levels despite a smaller workforce.

By automating the feeding process, flexible feeders can reduce the risk of workplace injuries that may occur from repetitive motion or heavy lifting.

With their ability to handle various part sizes and shapes, flexible feeders can minimize waste by ensuring that parts are properly oriented and placed in the correct position during the assembly process.

Assistance with Robot Options

This flexibility is an important feature of flexible feeding systems, as different lines require different types of robots and equipment, and flexible feeding systems can be configured and customized to meet these needs.

SCARA Robot

SCARA robots are characterized by high speed, high precision, high rigidity and large load, and are suitable for highly repetitive and fast assembly tasks, such as electronics, machinery, automotive and medical industries.

Collaborative Robot

Compared to traditional industrial robots, collaborative robots are more flexible and customizable, and they often use programmable control systems and sensor technology to sense their surroundings and make decisions based on real-time data.

Vision systems are able to identify parts of various shapes, sizes and types and determine their exact location on the production line. This data is then transmitted to robots or other automation equipment, enabling efficient and accurate part manipulation.

The vision system detects the orientation of parts to ensure they are correctly placed on the production line. If a part is misoriented, the vision system notifies the robot or other equipment to correct it, reducing error rates and improving production quality.

Vision systems can track the movement of parts on the production line in real time, ensuring continuity and consistency in the production process.

Vision systems can detect defects on parts, such as cracks, scratches or color inconsistencies. By detecting problems early, scrap rates can be reduced and production quality improved.

The data collected by the vision system can be used to further optimize the production process. By analyzing the data, the production line can be adjusted to improve efficiency and quality.

The vision system is ideal for flexible feeding systems because of its ability to recognize a wide range of shapes, sizes and types of parts. no matter what changes occur in the production line, the vision system can quickly adapt and keep running efficiently. performance of the system.

The role of the vision system in flexible feeding system

Vision systems play a critical role in the flexible feeding system. Through the use of cameras, image processing software and related hardware, vision systems can identify, locate and track material, thereby increasing the efficiency and accuracy of the production line. The following are the main roles of vision systems in a flexible feeding system.

The role of the hopper in a flexible feeding system

In a flexible feeding system, the hopper plays a crucial role in storing, regulating, and delivering parts to the next stage of the process. It works in conjunction with other components, such as conveyors, vibratory feeders, and robotic systems, to ensure a smooth and efficient operation.

The hopper stores a large volume of parts, reducing the frequency of manual refilling and minimizing downtime. This allows for continuous operation and increased productivity.

The hopper’s design, often featuring a tapered bottom, ensures a consistent and controlled flow of parts from the hopper to the next stage of the process, such as a vibratory feeder or conveyor.

Some hoppers come equipped with agitation or vibration systems that help to keep parts moving and prevent them from clumping or bridging, which could cause blockages and disrupt the feeding process.

Hoppers can be customized to handle a wide range of part sizes and shapes, making them suitable for use in flexible feeding systems where multiple part types may need to be processed.

Hoppers are designed to integrate seamlessly with other elements of a flexible feeding system, such as conveyors, vibratory feeders, and robotic systems. This ensures a smooth transition of parts from one stage of the process to another.

Some hoppers feature adjustable flow rates, allowing operators to fine-tune the delivery of parts to the flexible feeding system based on the specific requirements of the application. This can help optimize the overall performance of the system.

Areas of application for flexible feeding systems

Flexible feeding systems have a wide range of applications across various industries, thanks to their adaptability and ability to handle different part sizes, shapes, and materials.

Automotive industry

Flexible feeding systems are used for assembling various automotive components, such as engines, transmissions, electronics, and interior parts. They help streamline production and improve overall efficiency in the assembly process.

Electronics and consumer goods

These systems are utilized in the assembly of electronic devices like smartphones, tablets, and household appliances. They can handle delicate components with precision and speed, ensuring high-quality production.

Medical devices and pharmaceuticals

Flexible feeding systems are applied in the production and assembly of medical devices, such as surgical instruments, implants, and diagnostic equipment. They are also used for packaging pharmaceutical products like pills, capsules, and syringes.

Aerospace and defense

These systems are used in the assembly and production of aircraft components, satellites, and defense equipment, where precision and reliability are crucial.

Watch & Jewelry

Flexible feeding systems can also be utilized in the watch and jewelry industry, where precision and delicacy are crucial during the manufacturing and assembly processes.

5G Communications & Semiconductors

Flexible feeding systems have significant applications in the 5G communications and semiconductor industries, where precision, accuracy, and high throughput are essential. These systems are highly adaptable and can handle various component sizes, shapes, and materials, making them suitable for complex and delicate assembly processes.

Comparison

Advantages of Flexible Feeding System Over Traditional Loading Station

The traditional loading station is a common type of equipment used in production lines to transport parts and materials to the next stage of processing or assembly. Some of the key features of traditional loading workstations include.

Traditional loading workstations are typically designed for specific part types, sizes and shapes. This means that they work well with specific parts, but changing part types may require adjustments or replacement of equipment.

n some cases, traditional loading workstations may require manual operation, such as filling hoppers, adjusting equipment settings, or resolving clogs. This can increase labor costs and the risk of human error.

While many conventional loading workstations have some degree of automation, they typically do not have advanced vision systems, sensors and controllers. This can limit their ability to handle complex parts or adapt to diverse production needs.

Because traditional loading workstations are designed for specific components, it may take longer to realign or replace equipment when changing line configurations. This can result in longer downtime and reduced productivity.

Traditional loading workstations can take up a large amount of space, especially if they are required to handle large parts or high volume production. This can have an impact on plant layout, especially in environments where space is limited.

Traditional loading workstations may need to be customized for specific lines and components. While this can ensure that the equipment meets specific needs, it can also lead to higher initial investment costs and longer equipment replacement cycles.

The flexible feeding system has many significant advantages over traditional loading stations, making it a more effective and efficient solution in many industries and applications. The following are some of the key advantages of the flexible feeding system over traditional loading stations.

flexible feeding systems are capable of handling a wide range of part sizes, shapes and materials, which means they can be adapted to different line requirements without the need to replace the entire machine. In contrast, traditional feeding workstations are usually designed and optimized for specific parts only.

Because the flexible feeding system can handle a wide range of components, changeover times are significantly reduced when line configurations are changed. This helps to reduce downtime and increase productivity.

The flexible feeding system utilizes advanced vision systems, sensors and controllers to achieve a high level of automation, reducing the need for manual intervention. This reduces labor costs and improves the accuracy and consistency of the production line.

Productivity is increased because the flexible feeding system handles parts more quickly and accurately. This means higher throughput and lower scrap rates.

As production needs change, flexible feeding systems can be easily adjusted or reconfigured to handle new parts or increase throughput. This makes them a solution with future growth potential.

By automating the part loading process, flexible feeding systems can reduce the risk of human error. This helps to improve production quality and reduce scrap rates. adapt and keep running efficiently. performance of the system.

flexible feeding systems are often more compact and take up less space than traditional loading stations. This makes them easier to integrate into existing production lines or to use in factory environments where space is limited.

FAQs

Here are some Frequently Asked Questions (FAQs) for a flexible feeding system along with their answers:

The flexible feeding system can handle various types of parts and materials, including metal, plastic, rubber, glass, and ceramics. It can accommodate different sizes, shapes, and orientations, making it suitable for a wide range of industries and applications.

The flexible feeding system utilizes advanced vision systems and sensors to identify and orient different part sizes and shapes. This allows the system to adapt to variations in part geometry, ensuring accurate and consistent feeding to the assembly or processing equipment.

Flexible feeding systems can benefit various industries, including automotive, electronics, medical devices, aerospace, food and beverage, plastics and injection molding, metalworking, packaging, and logistics. They are suitable for applications that require precise and efficient handling of diverse part types and sizes.

he vision system in a flexible feeding system uses cameras and advanced image processing algorithms to identify, locate, and orient parts. The benefits of this system include improved accuracy, speed, and consistency in part handling, reduced reliance on manual labor, and the ability to handle a wide range of part types without requiring specialized equipment.

Flexible feeding systems are designed for easy integration with existing production lines and automation equipment, such as robotic arms and conveyors. They typically feature modular designs and standard communication protocols to ensure seamless integration and minimal disruption to the production process.

The throughput or production rate for a flexible feeding system depends on factors such as part size, shape, and complexity, as well as the system’s configuration and integration with other equipment. In general, flexible feeding systems offer higher throughput rates than traditional feeding workstations due to their ability to handle diverse part types and sizes more efficiently.

Yes, flexible feeding systems can be customized to meet specific production requirements, such as handling unique part types or accommodating specialized automation equipment. Manufacturers typically work closely with customers to design and configure systems that meet their unique needs and production goals. customized to meet specific production requirements?

Maintenance requirements for a flexible feeding system include regular inspection and cleaning of the equipment, as well as periodic calibration and adjustment of the vision system and sensors. Manufacturers typically provide detailed maintenance guidelines and schedules, as well as support and training to help customers maintain their systems effectively.

Flexible feeding systems offer greater efficiency, cost-effectiveness, and adaptability compared to traditional feeding workstations. They can handle a wider range of part types and sizes, reducing the need for specialized equipment and frequent changeovers. Additionally, they offer higher levels of automation and throughput, which can help improve overall production efficiency and reduce labor costs.

Q: What kin

Head Office Address

Shenzhen, China.

Email Address

ethan.z@ifeedering.com

Office Telephone & WhatsApp

+86 136 3298 0521