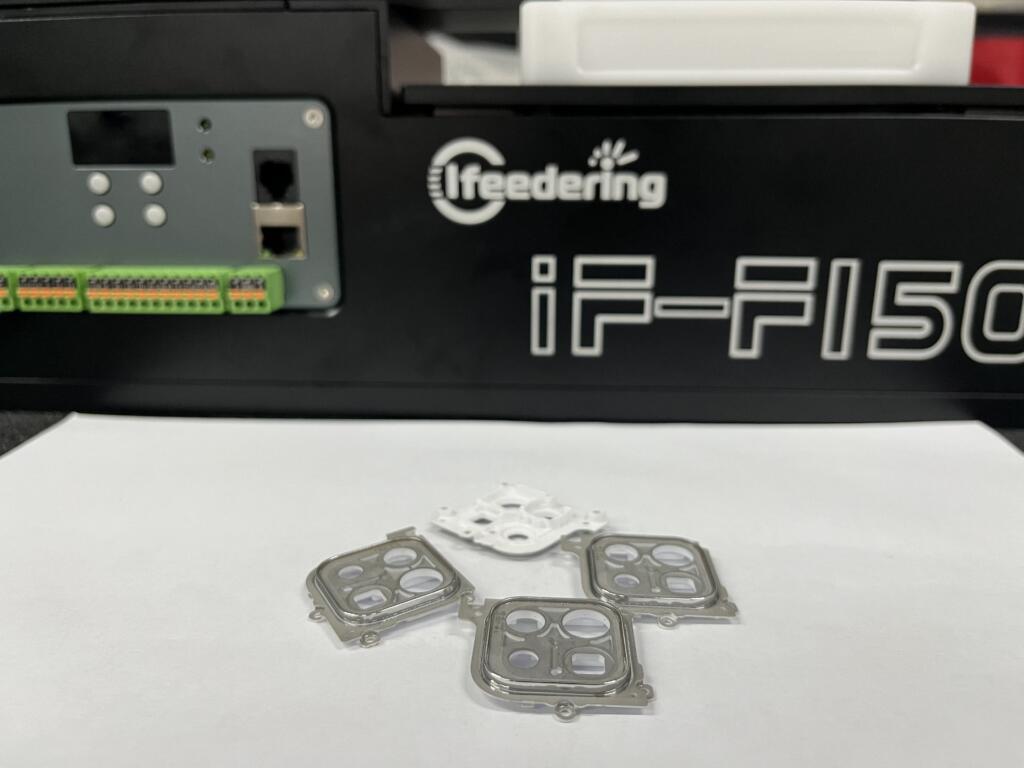

Automating Mobile Phone Camera Cover Handling with Flexible Feeders

we explore the innovative application of flexible feeders in the automation process for mobile phone camera covers. These small, delicate components present unique challenges for traditional feeder systems due to their precise handling and orientation requirements. Challenges in Mobile Phone Camera Cover Automation: Solutions with Flexible Feeders: Flexible feeders, like those from iFeedering, offer the […]

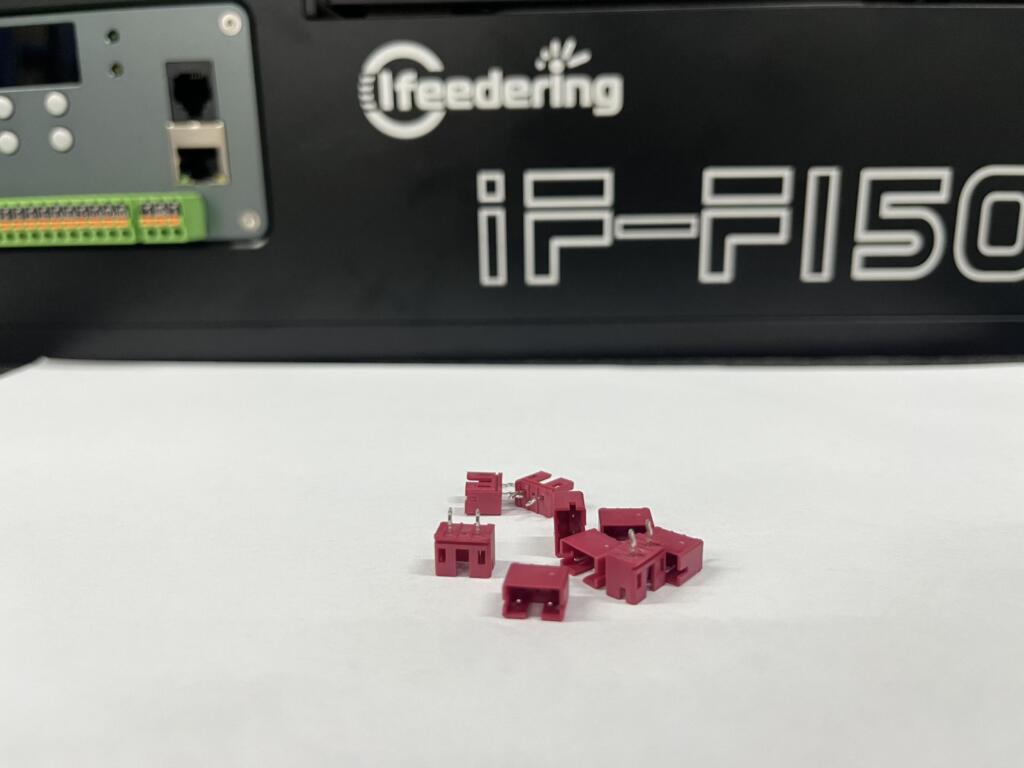

Enhancing Terminal Block Automation with Flexible Feeders

In this video, we delve into the challenges of automating the loading process for terminal blocks and how flexible feeders provide an effective solution. Terminal blocks, with their varying shapes and sizes, present significant challenges for traditional feeder systems. Ensuring precise orientation and gentle handling while maintaining high-speed operation is crucial. Challenges in Terminal Block […]

Enhancing Jewelry Automation with Flexible Feeders

As a professional deeply embedded in the automation industry, I’ve seen firsthand how challenging it can be to handle delicate and irregularly shaped materials like jewelry components. Automating the loading and unloading process for jewelry poses unique challenges that standard feeder systems often struggle to address. The irregular shapes, varying sizes, and delicate nature of […]

Automating Inductor Coil Loading with Flexible Feeder

As someone deeply involved in the automation industry, I understand the complexities of automating the loading process for inductor coils. These components are delicate, come in various shapes and sizes, and are sensitive to magnetic interference. Ensuring gentle handling, precise orientation, and minimizing tangling while maintaining high-speed operation is no small feat. However, I’ve found […]

Why Use a Flexible Feeder?

Flexible feeding is a viable alternative to traditional methods such as belt, bin, or bowl feeding in automated assembly or packaging. Unlike these methods, which often require specific adjustments or setups for different materials or components, flexible feeding offers adaptability and versatility. Flexible feeder can handle many different materials, no matter how big or small, […]

Why Use a Flexible Feeder?

In the world of manufacturing and assembly, efficiency and precision are key. One tool that has revolutionized these processes is the flexible feeder.

Top 5 flexible feeder brands

In the world of manufacturing and assembly, the flexible feeder is a game-changer. It’s a device that can handle a wide variety of parts, regardless of their size, shape, or material. This versatility makes the flexible parts feeder an essential tool for industries that require high-speed, precision-based feeding of various components. In this article, we […]

Introduction to the Flexible Feeder Technology

Flexible feeders are automated systems that are made to make the production process easier. They can feed, align, and transport parts to a production line.

Revolutionizing Automation: The Versatile Flexible Feeder

This article delves into the transformative impact of flexible feeders on the automation industry. Unveiling their capability to handle a wide variety of production materials and complex shapes, the piece underscores how these advanced systems are setting a new standard for versatility and efficiency in automated processes.

The Importance of Regular Maintenance in Flexible Feeder Systems

Flexible feeder systems are machines that rely on regular maintenance and upkeep to ensure they can continue to work efficiently. Without regular maintenance, they can become unreliable, inefficient and, in some cases, dangerous. In this article, we will discuss the importance of regular maintenance in flexible feeder systems, the benefits of doing so, and some […]