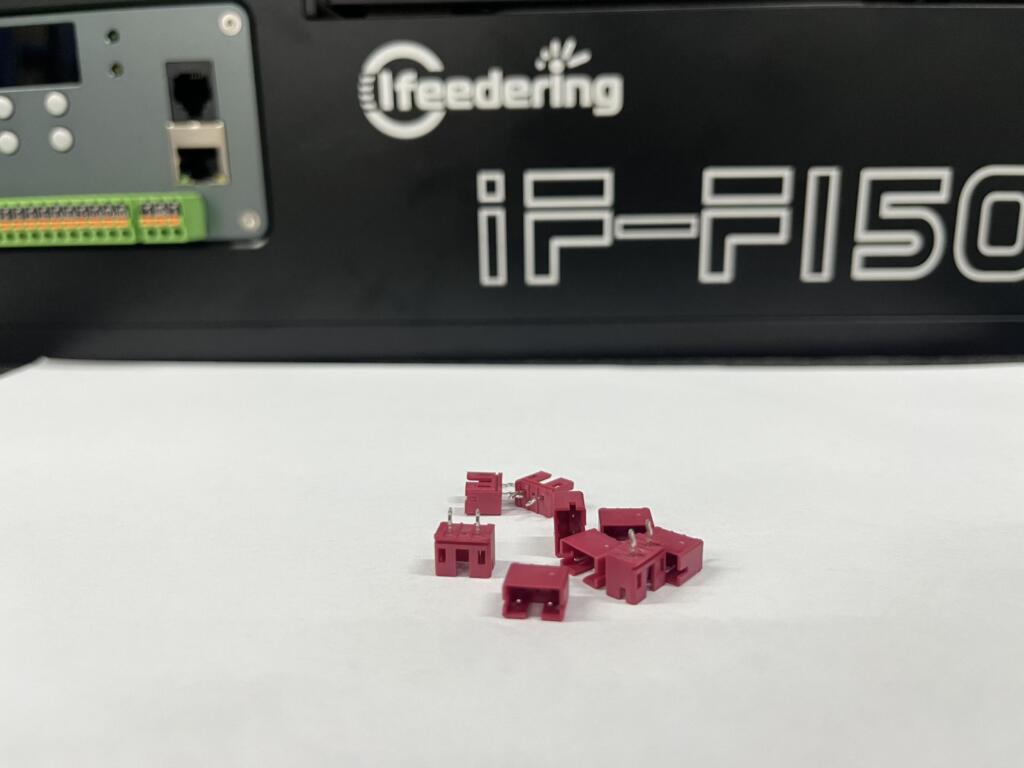

In this video, we delve into the challenges of automating the loading process for terminal blocks and how flexible feeders provide an effective solution. Terminal blocks, with their varying shapes and sizes, present significant challenges for traditional feeder systems. Ensuring precise orientation and gentle handling while maintaining high-speed operation is crucial.

Challenges in Terminal Block Automation:

- Shape and Size Variability: Terminal blocks come in different shapes and sizes, making it difficult for standard feeders to handle them efficiently.

- Precision and Orientation: Correct orientation is essential for terminal blocks to ensure reliable connections and functionality.

- Gentle Handling: Terminal blocks must be handled carefully to avoid damage, ensuring they remain functional and reliable.

- High-Speed and Volume Handling: In high-volume production environments, the feeder system needs to handle large quantities quickly and reliably.

Solutions with Flexible Feeders:

Flexible feeders, such as those from iFeedering, offer the perfect solution for these challenges:

- Adaptability: Handling various shapes and sizes without extensive reconfiguration, making them ideal for terminal blocks.

- Precision Control: Ensuring accurate orientation and placement, crucial for the correct functioning of terminal blocks.

- Gentle Handling: Designed to handle delicate components with care, reducing the risk of damage.

- High-Speed Operation: Efficiently handling large volumes to meet production targets without compromising quality.

By using iFeedering’s flexible feeders, you can enhance the automation process for terminal blocks, ensuring efficient, reliable, and high-quality operations. Watch the video to learn more about how our solutions can transform your manufacturing process.