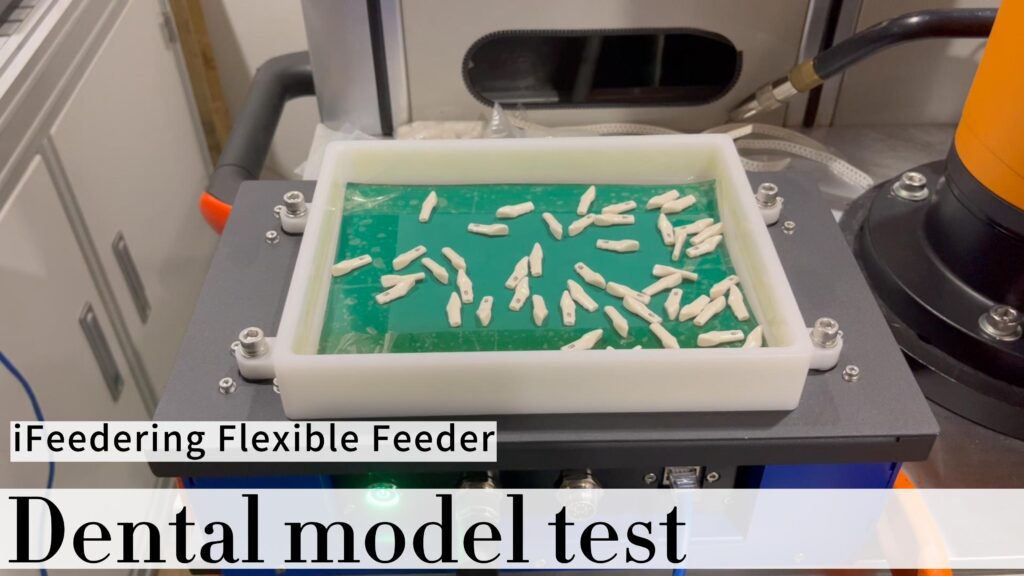

Load handling of complex, fragile parts

Flexible Feeder Systems have become increasingly popular in the industrial sector due to the stability and protection they offer. Flexible Feeders are more suitable for the feeding of complex and vulnerable parts. Thanks to Flexible Feeders, it is much easier for industrial robots to accurately identify components and adjust their vibration parameters if needed. Not only do Flexible Feeders provide improved precision, they can also effectively protect delicate components from damage during the production process. Flexible Feeder Systems are a high-performing and cost-effective solution that has revolutionized modern-day industrial operations.

Time savings

A flexible feeder system can significantly reduce the amount of time it takes to complete a task. This is because the system is able to automatically adjust to any given changes in production or workloads, meaning that tasks can be completed more quickly and efficiently than with manual processes. Furthermore, since the system is automated, it eliminates the need for human labor and supervision, resulting in even greater time savings.

Cost Savings

Flexible feeders can also provide businesses with significant cost savings. Since they are automated, they require less labor and supervision than manual processes would. Additionally, they help to optimize production processes, which can lead to fewer costly errors and mistakes down the line as well as reduced waste due to overproduction or underproduction. Finally, flexible feeders have a low maintenance cost compared to other types of feeder systems.

Quality Control

Flexible feeders also provide businesses with improved quality control by ensuring that products are produced consistently according to specified standards. The system’s automation ensures that all steps in a process are completed accurately and on-time without any human error or oversight necessary.

With the advantages that flexible feeder systems offer, it is no wonder that they are being adopted in a variety of industries. The ability to tailor the system to specific needs and budgets makes this technology an attractive option for companies looking to increase efficiency and bottom line profits. Have you considered implementing a flexible feeder system in your business?