Taking Assembly Automation to the Next Level of Flexibility

Unlock the Future with Adaptable, Cost-effective Feeding Systems.

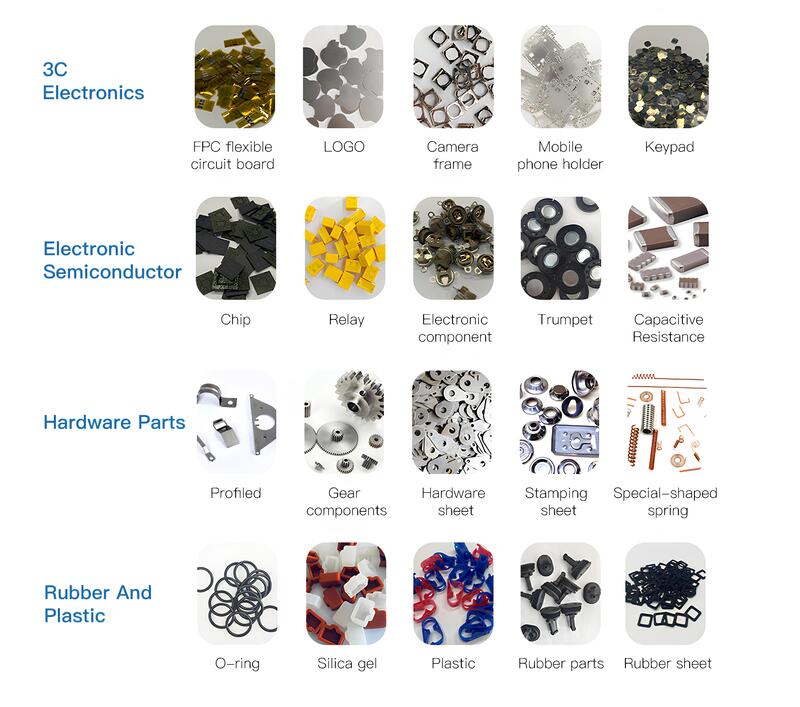

Broad Compatibility

Compatible with 99% of parts, our system handles a diverse array of geometric shapes, materials, and surfaces without scratching

Quick Flexibility

No need to switch out hardware. Our program offers one-key variety changes, perfect for small-batch, multi-spec production

Tailored Service

We offer custom trays and additional features like automatic clearing to meet your unique material and production needs

Our Project, Your Success

Meet our expert engineers who tailor automation solutions to fit your needs, save you money, and maximize results.” Solutions to fit your needs.

Key Features

Unlock the Future with Adaptable, Cost-effective Feeding Systems.

Basic Configuration

- The Beat:1.2~1.5 s/pcs

- Pressure: 0.5~0.7 mpa

- Precision: 1mm

- Suction nozzle : 2~15 mm

Optional

- Robot :Epson / UR / AUBO / DOBOT / KUKA

- CCD with Industrial Controller : customization

- Jaws : customization

- Structure : customization

Assembly Automation as Building Blocks

Effortless Scalability and Customization for Industry-Leading Efficiency

Why Choose Our Flexible Feeding Systems?

Your needs are unique; shouldn’t your automation solution be too? Discover unparalleled versatility with a system designed to adapt, not just perform.

Engineered Stability, Built to Last

Say goodbye to costly disruptions. Experience a new standard of reliability and efficiency that keeps your operations moving.

Compatibility, Not Complexity

Complex doesn't mean better. Our systems play well with others, easily integrating into your existing setup without hassle.

A Wise Investment for the Smart Operator

Lower costs, not expectations. Benefit from a system that requires less upkeep, allowing you to focus on what really matters.

Adapting to Multiple Industries and Materials

Unlock Seamless Integration and Material Flexibility Across Varied Industrial Applications

Application

Tape and Reel

Assembly Automation

Sorting Automation

CNC Loading

Medical Applications

Your Path to Automated Efficiency

From Initial Inquiry to Long-Term Support: A Seamless Journey Through Customized Assembly Automation

1

Initial Inquiry

Where Your Automation Journey Begins

2

In-Depth Discussion

Tailoring Solutions to Your Unique NeedsSolutions

3

Equipment Planning

Crafting a Customized Blueprint for Success

4

Customer Confirm

Finalizing Details for a Seamless Transition

5

Production Phase

Building Your Equipment with Precision and Care

6

Pre-Shipment Testing

Ensuring Operational Excellence Before Delivery

7

Secure Shipping

Bringing Your Customized Equipment to Your DoorstepCustom

8

Installation

Setting You Up for Immediate Success

What Client Says

Treating customers as partners

Your Purchase Helps Kids in Need

5% of Every Sale Supports the UN Kids Fund

When you partner with us for your automation needs, you’re also giving back. That’s because 5% of every sale you make with us goes directly to helping children through the UN Kids Fund. It’s more than just a business deal; it’s a way to make a positive impact on young lives.

Get A Free Quote

Contact us to get a free quote and more expertise about flexible feeders. Your project will meet the right solution with iFeedering.

The easier way to singulate bulk parts!

Tell Us What You Need

Please be as specific as possible about your needs, provide material drawings, dimensions, weights and share your ideas.

Get Solution & Quote

We will work on the best solution according to your requirements and drawing, the specific quote will be provided within 24 hours.