Introduction:

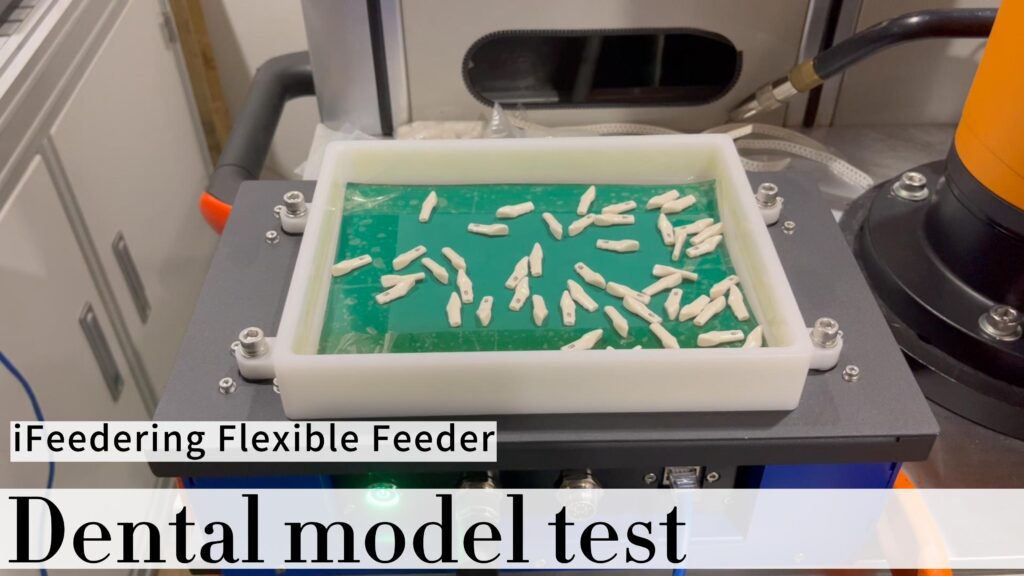

Flexible feeder systems are essential components of modern manufacturing processes. They enable the handling, sorting, and feeding of parts and components in an efficient and cost-effective manner.

In this comprehensive guide, we will explore the different types of flexible feeder systems, their applications, and the benefits they offer.

Types of Flexible Feeder Systems:

There are several types of flexible feeder systems available, each with its own advantages and disadvantages. The most common types are vibratory feeders, centrifugal feeders, and vision-guided feeders.

Vibratory feeders use vibration to sort and orient parts, while centrifugal feeders use centrifugal force.

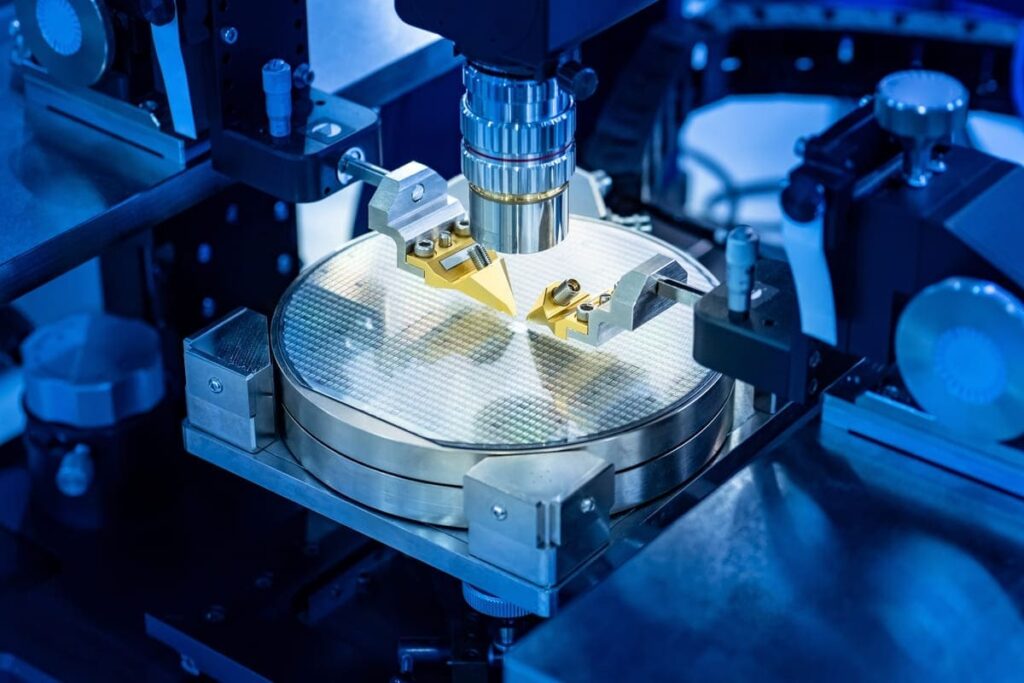

Vision-guided feeders use cameras and sensors to detect and sort parts.

Each type of feeder has its own unique advantages and applications, and the choice of which to use depends on the specific needs of the manufacturing process.

Applications of Flexible Feeder Systems:

Flexible feeder systems are used in a wide range of manufacturing applications, including automotive, electronics, medical, and aerospace.

They are ideal for handling small and fragile parts that require delicate handling, as well as larger parts that need to be sorted and oriented quickly and accurately.

Flexible feeder systems are also useful in applications that require high-speed production, as they can sort and feed parts at rates of up to 2,000 parts per minute.

Benefits of Flexible Feeder Systems:

Flexible feeder systems offer several benefits to manufacturers, including increased efficiency, reduced labor costs, and improved product quality.

They also reduce the risk of injury to workers, as they eliminate the need for manual handling of parts.

Flexible feeder systems are also highly customizable and can be adapted to handle a wide range of part sizes and shapes, making them an ideal solution for manufacturers with varying production requirements.

Considerations When Choosing a Flexible Feeder System:

When choosing a flexible feeder system, several factors should be considered, including the type of parts being handled, the required speed and accuracy, the flexibility and customization of the system, and the cost.

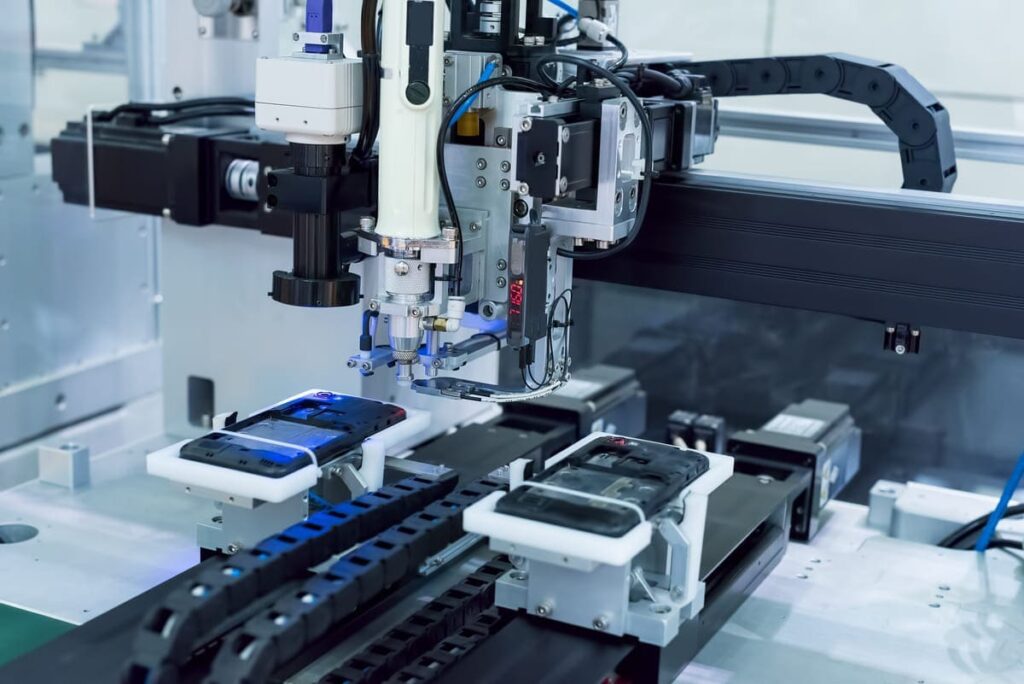

It is also important to consider the compatibility of the system with other automation equipment, such as robots and assembly machines.

Maintenance of Flexible Feeder Systems:

Regular cleaning and maintenance are essential to keep flexible feeder systems running smoothly.

It is important to follow the manufacturer’s guidelines for maintenance and cleaning, as well as to regularly inspect the system for wear and tear.

Any damaged or worn parts should be replaced immediately to prevent further damage to the system.

FAQs:

Q: What is the difference between a vibratory feeder and a centrifugal feeder?

A: Vibratory feeders use vibration to sort and orient parts, while centrifugal feeders use centrifugal force. Vibratory feeders are typically better suited for handling smaller parts, while centrifugal feeders are better suited for handling larger parts.

Q: How accurate are vision-guided feeders?

A: Vision-guided feeders are highly accurate and can sort and orient parts with an accuracy of up to 0.1mm.

Q: Can flexible feeder systems be integrated with other automation equipment?

A: Yes, flexible feeder systems can be integrated with other automation equipment such as robots, pick and place systems, and assembly machines.

Q: How long does it take to set up and install a flexible feeder system?

A: The setup and installation time of a flexible feeder system depends on the type and complexity of the system. A basic vibratory feeder can be set up in a few hours, while a more complex vision-guided feeder system may take several days.

Q: How do I know which type of flexible feeder system to choose?

A: The choice of which type of flexible feeder system to choose depends on the specific needs of the manufacturing process. Consider the type of parts being handled, the required speed, and accuracy.