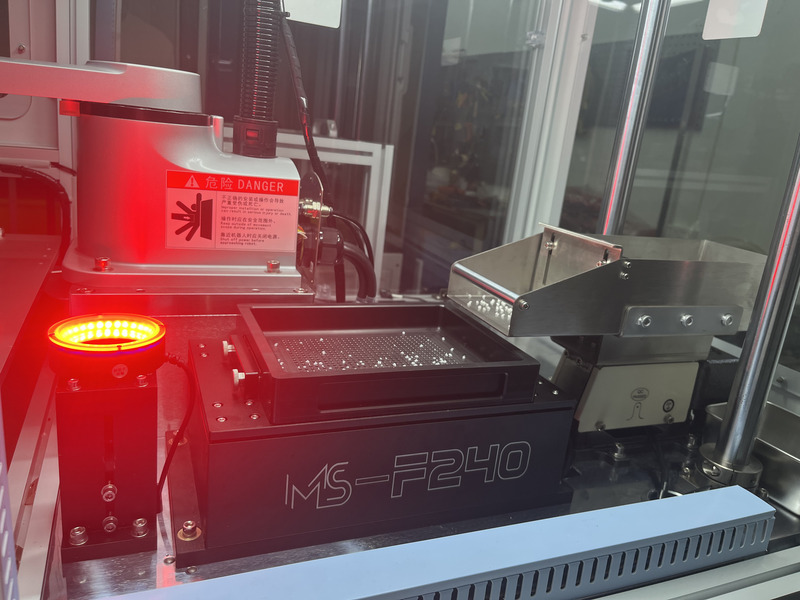

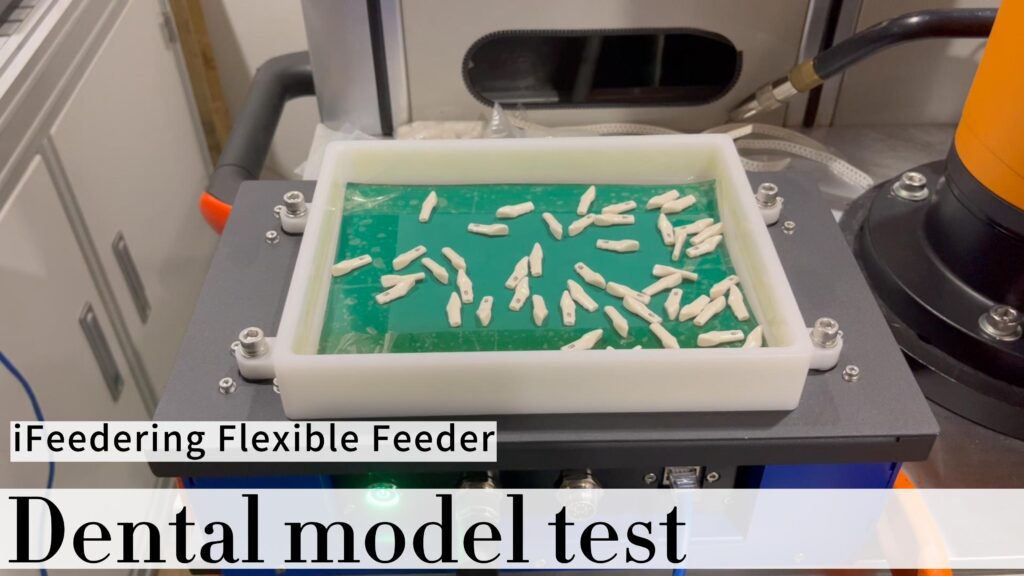

A flexible feeder is a type of machine that is used to feed and sort small parts and components in a production line. It is called flexible because it can be adjusted to handle different types of parts and can be easily integrated into various production processes.

The feeder consists of a conveyor belt or a bowl that moves the parts along a track. The track is designed with mechanisms that can sort and orient the parts based on their size, shape, and other properties. The feeder can also be equipped with sensors and cameras that help detect and sort the parts accurately.

Flexible feeders are commonly used in industries that require high-speed assembly and packaging of small parts, such as electronics, medical devices, and automotive manufacturing. They can help improve efficiency and accuracy, reduce waste, and minimize the risk of errors and defects.

Overall, flexible feeders are an essential tool for modern manufacturing, as they provide a reliable and flexible solution for sorting and feeding small parts in a fast-paced production environment.

Benefits of using flexible feeder

A flexible feeder is a versatile device that has become an integral part of modern industrial processes. It is designed to feed and orientate components, parts, and products with a high degree of accuracy and speed. The benefits of flexible feeders in industrial applications are numerous and include increased productivity, improved efficiency, and reduced costs.

One of the main benefits of flexible feeders is their ability to handle a wide range of components and products. They are designed to work with different shapes, sizes, and materials, making them ideal for use in diverse industrial applications. This flexibility means that a single feeder can be used for multiple products or components, eliminating the need for multiple feeders and reducing costs.

Flexible feeders are also known for their speed and accuracy. They are capable of feeding components and products at high speeds, increasing productivity and efficiency. They can also be programmed to feed products in a specific orientation, ensuring that they are properly aligned and positioned for downstream processes. This reduces the risk of errors and defects, improving product quality and reducing waste.

Another advantage of flexible feeders is their ease of use and maintenance. They are designed to be user-friendly, with intuitive controls and easy setups. This reduces the need for extensive training and minimizes downtime due to equipment malfunctions or breakdowns. Flexible feeders are also designed to be easy to clean and maintain, ensuring that they remain in optimal condition for longer periods.

Flexible feeders also have the advantage of being adaptable to changing production requirements. As products and components change, flexible feeders can be easily reconfigured or adjusted to accommodate these changes. This makes them ideal for use in industries where products and components are constantly evolving, such as the electronics and automotive industries.

In conclusion, the benefits of flexible feeders in industrial applications cannot be overstated. They offer increased productivity, improved efficiency, reduced costs, and ease of use and maintenance. With their versatility, speed, and accuracy, they are a vital component of modern industrial processes and will continue to play a significant role in manufacturing and production in the future.

The importance of using flexible feeder products in various industries

Flexible feeder products play a crucial role in various industries by simplifying the process of material handling and assembly. These products are designed to feed, sort, and orientate different types of parts, such as screws, nuts, bolts, and other small components, in an efficient and cost-effective manner.

One of the main advantages of flexible feeder products is their versatility. They can handle different shapes, sizes, and materials of parts, allowing manufacturers to use them in a wide range of applications. Moreover, flexible feeders are easy to set up and adjust, making them ideal for small-batch production and prototyping. manufacturers to use them in a wide range of applications.

In addition to their versatility, flexible feeders can significantly improve the overall productivity and efficiency of the production process. They can work at high speeds and can handle large volumes of parts, reducing the need for manual labor and increasing throughput. Furthermore, flexible feeders can reduce the risk of errors and inconsistencies, which can lead to higher-quality products and fewer defects.

Overall, the use of flexible feeder products is essential for various industries that require automated material handling and assembly. By using these products, manufacturers can save time, reduce costs, and improve the overall efficiency of their production process.

Advantages of using flexible feeder products

Flexible feeder products are a type of industrial equipment used in manufacturing processes to efficiently and accurately feed parts and components to machines. These products offer several advantages over traditional feeder systems, including: manufacturing processes to efficiently and accuratelyproduce a variety of products. They can handle parts.

Versatility: Flexible feeder products are designed to handle a wide range of part sizes and shapes, making them ideal for use in industries that produce a variety of products. They can handle parts as small as a few millimeters or as large as several inches in size.

Speed: Flexible feeder products are capable of feeding parts at high speeds, which can improve the efficiency of the manufacturing process. They can feed parts at rates of up to 1,000 parts per minute, depending on the specific product.

Customization: Flexible feeder products can be customized to meet the specific needs of a manufacturing process. This includes adjusting the feeding speed, adapting to changes in part sizes and shapes, and integrating with other equipment in the production line.

Reduced Downtime: Flexible feeder products are designed to minimize downtime in the manufacturing process. They can be quickly and easily adjusted to handle different parts, reducing the time needed for changeovers and maintenance. manufacturing process. They can be quickly and easily adjusted to

Improved Accuracy: Flexible feeder products use advanced sensing technology to ensure accurate part feeding. This helps to reduce errors in the manufacturing process and improve the quality of the finished products.

Overall, flexible feeder products offer many advantages over traditional feeder systems, making them an excellent choice for manufacturers looking to improve their efficiency, productivity, and quality.

Flexible feeders boost efficiency and productivity

Flexible feeders are a type of automated feeding system used in manufacturing and assembly operations. They are designed to increase efficiency and productivity by streamlining the process of supplying parts and components to automated machinery. manufacturing and assembly operations. They are designed to increase efficiency and productivity by streamlining the process of supplying parts and components

One of the key benefits of flexible feeders is their ability to handle a wide range of parts and components. Unlike traditional feeding systems, which are often designed to handle only one or a limited number of parts, flexible feeders can be easily reconfigured to accommodate different parts and components. This means that manufacturers can use the same feeder for multiple product lines or manufacturing processes, reducing the need for costly retooling and minimizing downtime.

Another advantage of flexible feeders is their ability to adapt to changing production requirements. As manufacturing operations evolve, the types and quantities of parts and components required may change. Flexible feeders can be easily modified to accommodate these changes, allowing manufacturers to respond quickly to shifts in demand and optimize their production processes. manufacturing operations evolve, the types and quantities of parts and components required may change. Flexible feeders can be easily modified to accommodate these changes, allowing manufacturers to respond quickly to shifts in demand and optimize their

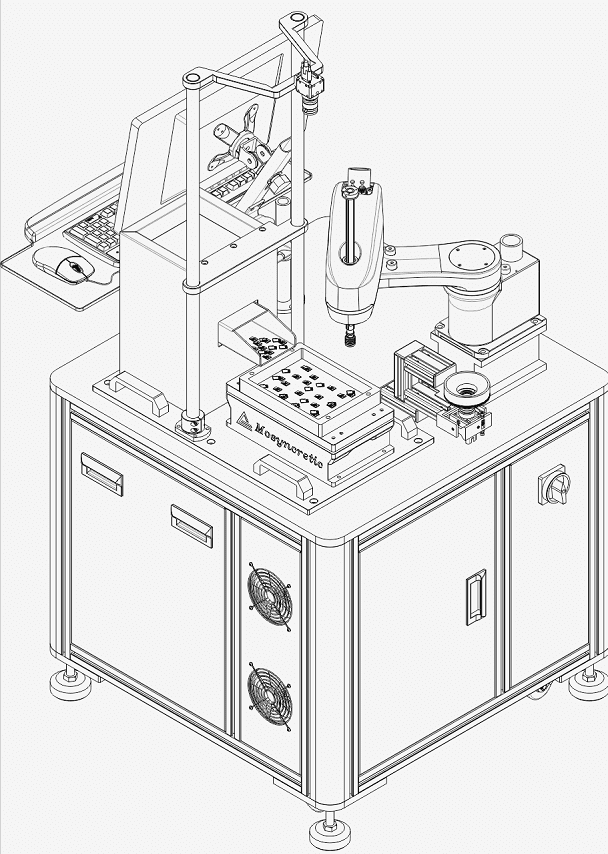

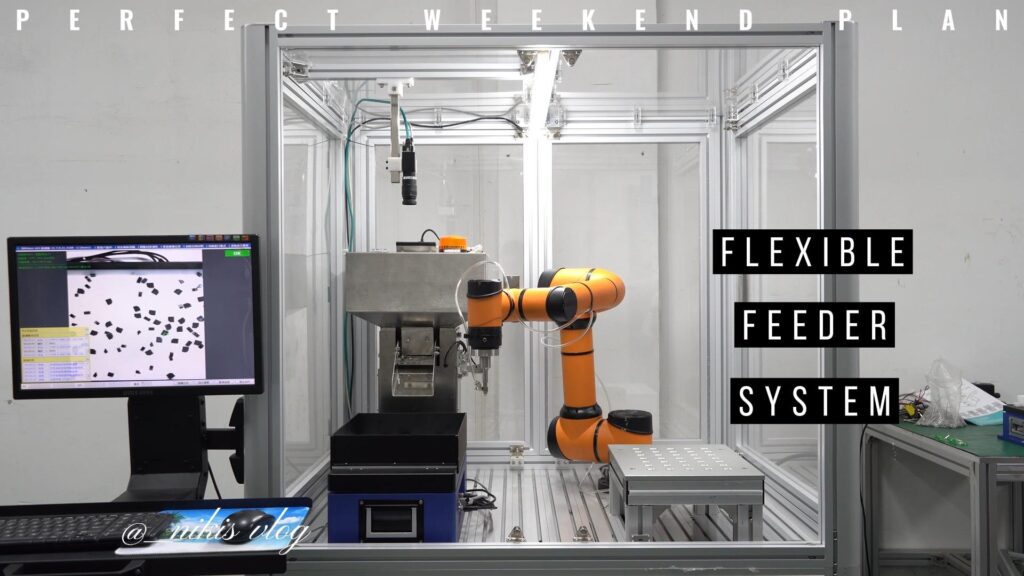

Flexible feeders can also be integrated with other automated systems, such as robotics and vision systems. This allows for even greater efficiency and productivity gains, as parts can be quickly and accurately identified and placed into position, minimizing the risk of errors and reducing the need for manual intervention.

Overall, the use of flexible feeders in manufacturing and assembly operations can lead to significant efficiency and productivity gains. By enabling manufacturers to handle a wide range of parts and components, adapt to changing production requirements, and integrate with other automated systems, flexible feeders can help to streamline manufacturing processes, reduce costs, and increase throughput. manufacturing and assembly operations can lead to significant efficiency and productivity gains. By enabling manufacturers to handle a wide range of parts and components, adapt to changing production requirements, and integrate with other automated systems, flexible feeders can help to streamline manufacturing processes, reduce costs, and increase manufacturing and assembly operations.

Reduced downtime and maintenance costs

Flexible feeders have become a popular solution in many manufacturing industries due to their ability to reduce downtime and maintenance costs. These feeders are designed to adapt to various shapes and sizes of parts, allowing them to handle a wide range of products. solution in many manufacturing industries due to their ability to reduce downtime and maintenance costs. These feeders are designed to adapt to various shapes and sizes of parts, allowing them solution in many manufacturing industries due to

One way that flexible feeders have reduced downtime is by eliminating the need for tooling changes. Traditional feeders require specific tooling for each part, which can be time-consuming and costly to change. With flexible feeders, the same feeder can handle a variety of parts without any tooling changes, reducing setup time and increasing productivity.

In addition to reducing setup time, flexible feeders also require less maintenance than traditional feeders. Since they don’t require specific tooling, there are fewer parts to maintain and replace. Flexible feeders also use fewer mechanical parts, reducing the chances of breakdowns and increasing reliability.

Another benefit of flexible feeders is their ability to reduce the need for manual labor. With traditional feeders, operators often need to manually load and unload parts. Flexible feeders can be integrated with robots, allowing for automated loading and unloading, reducing the need for manual labor and increasing efficiency.

Overall, flexible feeders have become a valuable asset to many manufacturing industries due to their ability to reduce downtime, maintenance costs, and the need for manual labor. As technology continues to advance, it’s likely that flexible feeders will become even more common in manufacturing facilities around the world. manufacturing industries due to their ability to reduce downtime, maintenance costs, and the need for manual labor.

Enhanced accuracy and precision

Flexible feeders are automated systems that use advanced technology to move, sort and orient parts in the manufacturing process. They are designed to handle parts of varying shapes, sizes and materials, and they can be customized to meet specific production requirements. These feeders can enhance accuracy and precision in several ways.

Firstly, flexible feeders can improve accuracy by eliminating errors that occur during manual feeding. Manual feeding is prone to errors such as misalignment, incorrect orientation and incorrect placement, which can compromise the quality of the final product. With flexible feeders, parts are automatically aligned and positioned correctly, reducing the risk of errors and improving accuracy.

Secondly, flexible feeders can enhance precision by providing consistent part placement. The feeders are programmed to handle parts in a specific way, ensuring that they are positioned precisely every time. This level of precision can be difficult to achieve with manual feeding, which is subject to variations in operator skill and fatigue.

Thirdly, flexible feeders can improve accuracy and precision by reducing the time required for feeding. Flexible feeders can handle parts at a much faster rate than manual feeding, which can reduce the risk of production delays and increase throughput. This increased speed also reduces the risk of errors, as the feeders can handle parts more quickly and accurately than humans.

Finally, flexible feeders can improve accuracy and precision by reducing the risk of part damage. Manual feeding can be rough on parts, particularly those that are fragile or delicate. Flexible feeders are designed to handle parts gently, reducing the risk of damage and ensuring that the parts are in good condition when they are used in the manufacturing process.

In conclusion, flexible feeders can enhance accuracy and precision in manufacturing processes by eliminating errors, providing consistent part placement, reducing feeding time, and reducing the risk of part damage. They are a valuable investment for any manufacturer looking to improve the quality of their products and increase production efficiency.

Flexibility and adaptability to different materials and production processes

A flexible feeding system is a critical component of any modern manufacturing process, enabling the efficient and accurate delivery of parts to the assembly line. With the ever-increasing demand for flexibility and adaptability in production processes, a flexible parts feeding system has become an essential tool for meeting the diverse needs of manufacturers. manufacturing process, enabling the efficient and accurate delivery of parts to the assembly line. With the ever-increasing demand for flexibility and adaptability in production processes, a flexible parts feeding system has become an essential tool for meeting the diverse needs manufacturing process, enabling the efficient and accurate delivery of parts to the assembly line.

A flexible feeding system can adapt to a wide range of materials and production processes, providing a cost-effective and efficient solution for manufacturers. These systems use advanced technology to sort and orient parts, ensuring that they are delivered to the assembly line in the correct orientation and at the correct time. solution for manufacturers. These systems use advanced technology

One of the key benefits of a flexible parts feeding system is its ability to handle a wide range of parts, from small electronic components to larger mechanical parts. These systems can accommodate different shapes, sizes, and materials, making them ideal for use in a variety of industries, including automotive, electronics, and medical device manufacturing.

Moreover, a flexible feeding system can be easily adapted to different production processes, such as assembly lines, pick and place systems, and robotics. This versatility makes it an ideal solution for manufacturers who need to adapt to changing production needs quickly.

The benefits of a flexible feeding system extend beyond just flexibility and adaptability. These systems can also increase efficiency and productivity, reduce labor costs, and improve quality control. By automating the feeding process, manufacturers can reduce errors and improve the accuracy of part delivery, leading to a more efficient and streamlined production process. manufacturers can reduce errors and improve the accuracy of part delivery, leading to a more efficient

In conclusion, a flexible feeding system is an essential tool for manufacturers looking to improve flexibility and adaptability in their production processes. With the ability to handle a wide range of parts and production processes, these systems can provide a cost-effective and efficient solution for modern manufacturing needs. Keywords: flexible feeding system, flexible parts feeding system. manufacturers looking to improve flexibility and adaptability in their production processes.

Application of flexible feeder products

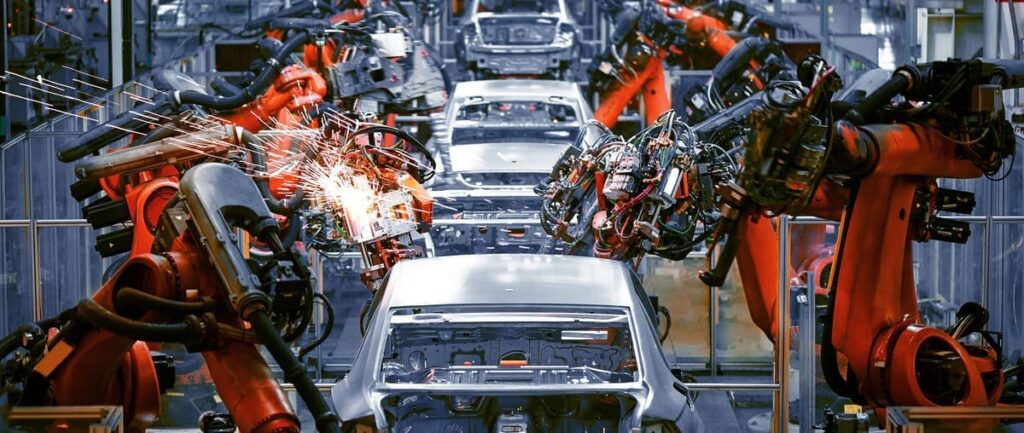

Automotive Industry

In the automotive industry, flexible feeders play a crucial role in the manufacturing process. These feeders are designed to handle a wide range of parts with varying sizes, shapes, and weights. They are highly versatile and can be easily adapted to meet the changing production requirements. Here are some of the advantages of flexible feeders in the automotive industry: manufacturing process. These feeders are designed to handle a wide range of parts with varying sizes, shapes, and weights. They are highly versatile and can be easily adapted to meet the changing production requirements. Here are some of the advantages of flexible feed manufacturing process. These feeders are designed to handle a wide range of parts with varying sizes, shapes, and weights.

Increased efficiency: With flexible feeders, automotive manufacturers can achieve a high level of efficiency. These feeders are designed to handle multiple parts at once, and they can quickly adapt to different parts.

Reduced labor costs: Flexible feeders can be operated by a single operator, which helps to reduce labor costs. The operator can easily switch between different parts without needing any additional assistance, which saves time and money.

Improved safety: Flexible feeders are designed to prevent jams and other safety hazards, which can lead to injuries or damage to the machinery. This ensures that the production process is safer and more reliable.

Higher quality output: Flexible feeders can handle delicate parts with precision, which results in higher quality output. They can also detect and remove defective parts, ensuring that only high-quality parts are used in the manufacturing process.

Faster changeovers: Flexible feeders can be quickly reconfigured to handle different parts, which reduces changeover times. This means that the production line can be quickly adapted to meet the changing demands of the market.

Overall, flexible feeders are an essential component of the automotive industry. They help to increase efficiency, reduce labor costs, improve safety, produce higher-quality output, and enable faster changeovers. Automotive manufacturers that invest in flexible feeders can gain a competitive edge and position themselves for long-term success.

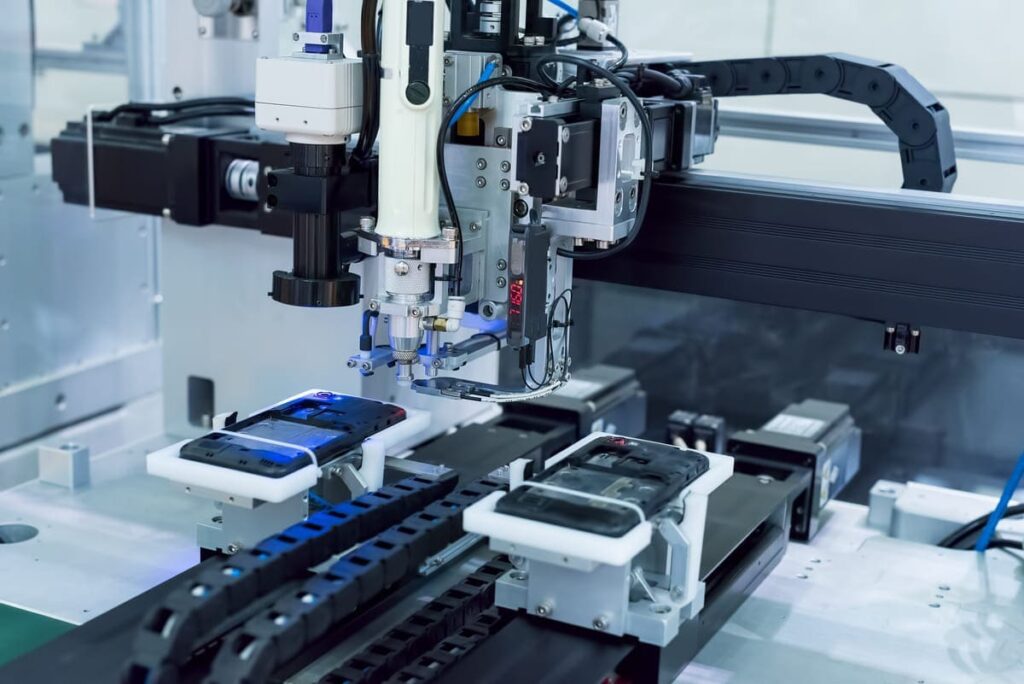

Electronics Industry

A flexible feeder is an essential component in the electronics industry, used to efficiently feed electronic components during assembly. Flexible feeders are designed to adapt to different types and sizes of components, allowing for maximum flexibility and versatility in the assembly process.

The electronics industry is characterized by high-volume production and a wide range of component sizes and shapes, making the use of traditional rigid feeders inefficient and costly. Flexible feeders are specifically designed to overcome these challenges by providing a customizable and adaptable solution for component feeding.

Flexible feeders use advanced technology such as vibration and artificial intelligence to ensure that the components are delivered to the assembly line in a consistent and reliable manner. The feeders can handle a wide range of components, from small surface-mount devices to larger through-hole components.

One of the main advantages of using flexible feeders in the electronics industry is the ability to reduce setup time and increase production efficiency. As the feeder can be quickly and easily adjusted to accommodate different components, it eliminates the need for multiple feeders for different component sizes, reducing costs and increasing productivity.

Additionally, flexible feeders are highly reliable, with a low risk of component jamming or misfeeds. This results in a higher yield rate and reduces the need for costly rework or repairs.

Overall, the use of flexible feeders in the electronics industry is critical to achieving efficient and cost-effective production processes. Their adaptability, reliability, and flexibility make them an indispensable tool in modern electronics manufacturing.

Food and beverage industry

Flexible feeders are becoming increasingly popular in the food and beverage industry due to their ability to handle a wide range of products, shapes, and sizes. These feeders are designed to optimize the feeding process, increase efficiency, and reduce the risk of contamination.

Pharmaceutical industry

Flexible feeders are an innovative technology used in the pharmaceutical industry to automate and streamline the process of feeding pharmaceutical components into machines. These feeders are specifically designed to handle and orient a wide range of components, such as pills, tablets, and capsules, with varying shapes, sizes, and textures.

The use of flexible feeders in the pharmaceutical industry offers several benefits, including increased efficiency, accuracy, and safety. By automating the feeding process, flexible feeders can significantly reduce the time and labor required to manually sort and load components into machines. This helps to increase production capacity, reduce costs, and improve product quality.

Flexible feeders are also highly accurate, which is critical in the pharmaceutical industry where precision is essential. They can reliably and consistently orient and place components in the correct position and orientation, ensuring that they are properly processed and packaged. This helps to prevent errors and defects, which can have serious consequences in pharmaceutical manufacturing.

In addition to improving efficiency and accuracy, flexible feeders also enhance safety in the pharmaceutical industry. By automating the feeding process, they can help to reduce the risk of workplace injuries and accidents that can occur when handling and sorting components manually. This helps to create a safer and more productive work environment for employees.

Other industries that can benefit from flexible feeder products

Flexible feeders are a type of automation technology that can be used in a variety of industries to improve productivity, efficiency, and profitability. Here are some industries that could benefit from flexible feeders:

Manufacturing: Medical device manufacturing requires precision and accuracy, making flexible feeders an excellent choice for automating the assembly process. With flexible feed

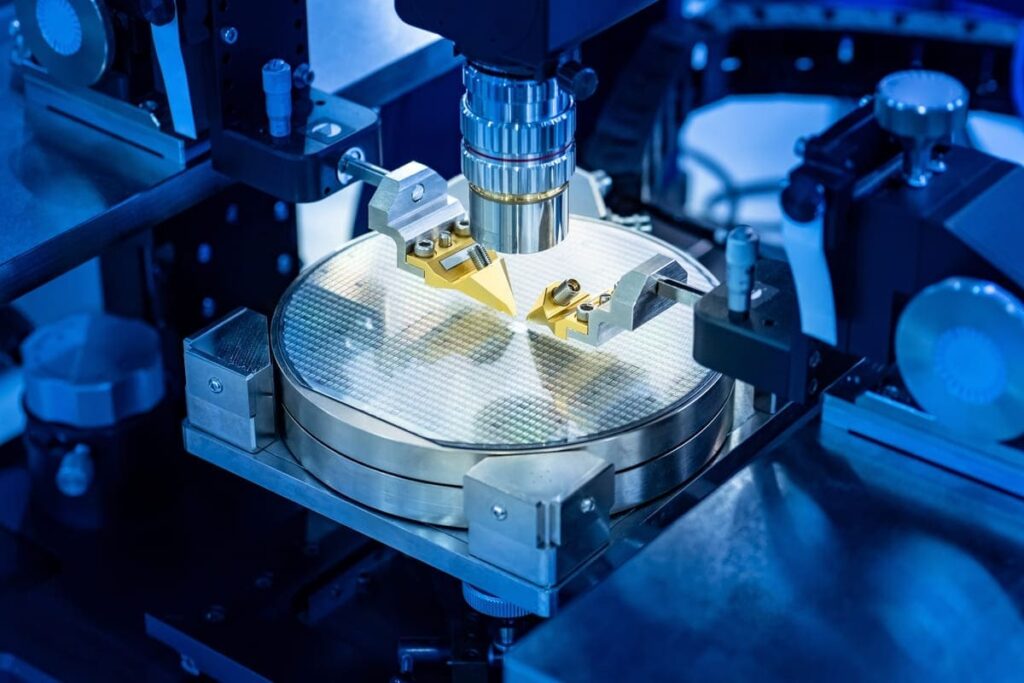

Medical Device Manufacturing: Medical device manufacturing requires precision and accuracy, making flexible feeders an excellent choice for automating the assembly process. With flexible feeders, medical device manufacturers can achieve faster assembly times, lower labor costs, and higher quality products.

Consumer Electronics: Flexible feeders can be used in the consumer electronics industry to automate the assembly of small components, such as circuit boards and sensors. This can lead to faster production times, improved product quality, and reduced costs.

How Flexible Feeder Products Work

A flexible feeder is a machine that is designed to sort, orient, and feed parts and components in a manufacturing or assembly line. It typically consists of a conveyor system, sensors, and mechanical components such as rollers or brushes that can adjust to accommodate different shapes and sizes of parts. manufacturing or assembly line. It typically consists of a conveyor system, sensors, and mechanical components such as rollers or brushes that can adjust to accommodate different shapes in manufacturing or assembly lines. It typically consists of a conveyor system, sensors, and mechanical components such as a manufacturing or assembly lines. It typically consists of a conveyor system, sensors manufacturing, or assembly line.

Technologies and mechanisms used in flexible feeder products

Flexible feeder technology and mechanism refer to the design and implementation of equipment that can handle a wide range of products with varying shapes, sizes, and materials. This technology is used in the manufacturing industry to automate the feeding and orientation of parts, components, and materials in assembly lines.

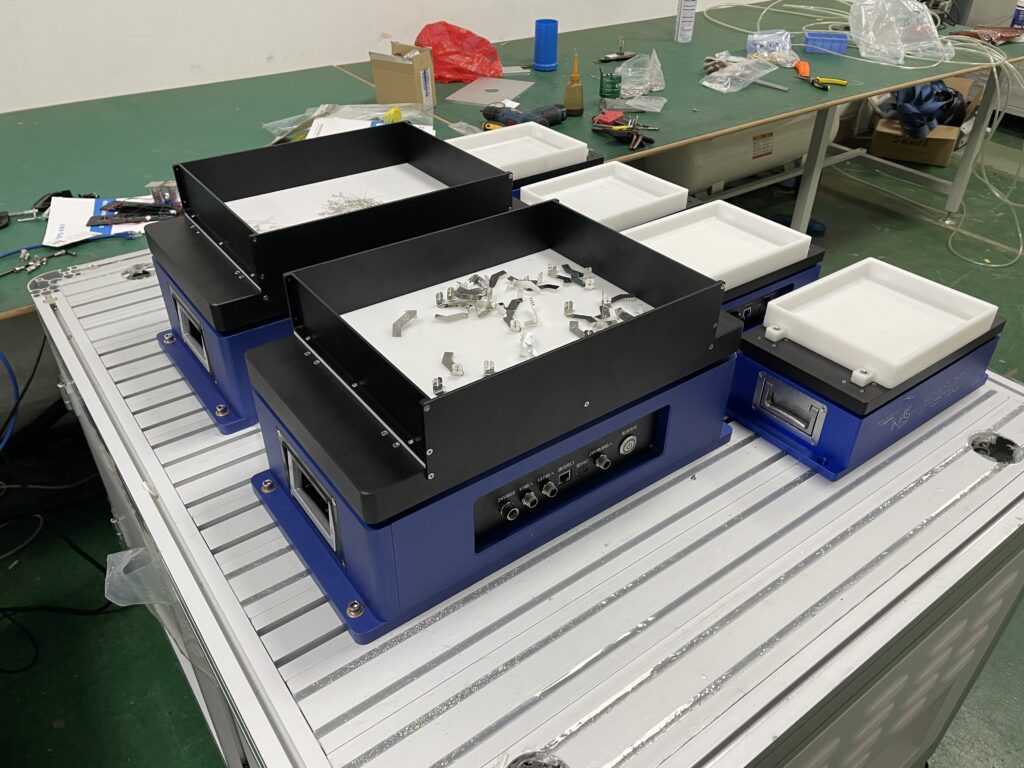

Flexible feeders employ a variety of techniques and mechanisms to accomplish their tasks. One common approach is the use of vibration to sort and orient parts. Vibratory feeders use electromechanical or electromagnetic drives to generate vibrations that cause the parts to move along a track or chute. The vibrations can be adjusted to match the size and weight of the parts, ensuring that they are properly positioned for assembly.

Another approach is the use of pneumatic systems, which employ air pressure to transport and position parts. Pneumatic feeders use a series of tubes and valves to create a vacuum or pressure that moves parts from one location to another. They can also be used to sort and orient parts using air jets or suction cups.

Flexible feeders can also incorporate computer vision and sensing technology to identify and track parts as they move through the system. This allows the equipment to adjust its operations in real time, ensuring that parts are properly positioned and aligned for assembly.

Overall, the goal of flexible feeder technology is to automate the feeding and orientation of parts in manufacturing processes, reducing the need for manual labor and improving efficiency and productivity.

Different types of flexible feeder products and their characteristics

Flexible feeder products are designed to handle a wide range of parts and materials with varying sizes, shapes, and weights. These products are widely used in industries such as manufacturing, packaging, and material handling. Here are some of the different types of flexible feeder products and their characteristics:Manufacturing

Vibratory Feeders – Vibratory feeders are the most commonly used type of flexible feeder. They use vibration to move parts and materials along a conveyor or tray. Vibratory feeders are ideal for handling fragile or delicate parts as they can be tuned to provide gentle handling. They are also suitable for high-speed applications and can handle a wide range of parts.

Centrifugal Feeders – Centrifugal feeders use centrifugal force to move parts and materials along a conveyor. They are suitable for handling small, lightweight parts and are commonly used in industries such as pharmaceuticals and electronics.

Belt Feeders – Belt feeders use a belt to transport parts and materials. They are suitable for handling heavy parts and are commonly used in industries such as automotive and construction.

Screw Feeders – Screw feeders use a rotating screw to move parts and materials. They are suitable for handling small parts and are commonly used in industries such as food and beverage.

Vacuum Feeders – Vacuum feeders use suction to transport parts and materials. They are suitable for handling fragile or delicate parts and are commonly used in industries such as electronics and pharmaceuticals.

Step Feeders – Step feeders use a series of steps to move parts and materials along a conveyor. They are suitable for handling small parts and are commonly used in industries such as automotive and electronics.

Overall, the characteristics of flexible feeder products depend on the specific type of feeder being used. However, some common characteristics of flexible feeder products include their ability to handle a wide range of parts and materials, their suitability for high-speed applications, and their gentle handling of delicate or fragile parts. Additionally, flexible feeder products are designed to be easy to maintain and operate, with user-friendly interfaces and intuitive controls.

Factors to consider when selecting flexible feeder products

When choosing a flexible feeder, there are several factors to consider to ensure that the feeder will meet your specific needs. Here are some important factors to consider:

Part size and shape: The size and shape of the parts you will be feeding should be taken into account when selecting a flexible feeder. Some feeders may not be suitable for larger or irregularly shaped parts, so make sure the feeder can accommodate your specific parts.

Material type: The type of material the parts are made of can affect the feeding process. Some materials may require specific feeders or modifications to the feeder to ensure proper feeding.

Feeding rate: The rate at which the parts need to be fed is an important consideration. Some feeders may not be able to keep up with high-speed production lines, so make sure the feeder can handle your required feeding rate.

Changeover time: If you will be using the feeder for multiple types of parts, consider how quickly the feeder can be reconfigured for different parts. A longer changeover time may result in decreased productivity.

Compatibility with downstream equipment: The feeder should be compatible with the downstream equipment, such as sorting and packaging machinery, to ensure a smooth production process.

Maintenance requirements: Consider the maintenance requirements of the feeder, including cleaning and replacing parts, to ensure that the feeder can be easily and efficiently maintained.

Cost: Finally, consider the cost of the feeder, including the initial purchase price, ongoing maintenance costs, and any necessary modifications, to ensure that it fits within your budget.

Companies can try to introduce flexible feeder

A flexible feeder is a versatile and adaptable system that can handle a variety of products and parts, making it ideal for use in many different industries.

There are several benefits to using flexible feeders. First, they can save you time and money by reducing the need for manual labor and increasing efficiency. With a flexible feeder, you can automate the feeding process, which means that you can focus on other aspects of your operations.

Second, flexible feeders are incredibly adaptable. They can be configured to handle a wide range of product shapes and sizes, so you can use them for different projects and products. This versatility also means that you can use the same feeder for multiple products, which can save you money on equipment costs.

Finally, flexible feeders can help you improve your quality control. They can be programmed to detect and reject defective products, which can help you reduce waste and improve your overall product quality.

In conclusion, I strongly encourage you to consider using flexible feeders in your operations. They can save you time and money, improve your efficiency, and help you maintain high-quality standards. By investing in a flexible feeder, you can take your operations to the next level.