iF-F150

iF-F240

iF-F380

iF-F530

What is the Flexible Feeder ?

The flexible feeder is a special vibrating plate that is good for many types of materials and parts. It can spread out small and funny-shaped parts and can be made to work with machines that can see and pick up parts. This is useful in making things move automatically from one place to another.

How does a flexible feeder works?

A flexible feeder uses a vibrating platform and a vision system to orient scattered parts into a single layer. Once oriented, a robot or mechanism picks and places them for the next process. This system is ideal for quickly adapting to different parts in low to medium-volume production.

iF-F150 Flexible Feeder

Feature: Hopper integrated with flexible feeder

| iF-F150 Specification | |

|---|---|

| Base Size | 420*135*134mm |

| Tray Size | 100*150*25mm |

| Tray load | 1kg |

| Applicable size | 0.5~15mm |

| Hopper volume | 2L |

| Hopper size | 100*203*30mm |

| Move type | up, down, left, right, up-left, up-right, down-left, down-right, disperse, compact |

| Communication | Modus TCP, Modbus RTU |

| Adaptive Products | Gemstones watch parts, and small medical or electronic components |

| Power Supply | 24V DC |

iF-F240 Flexible Feeder

Feature: Wide range of applicability

| iF-F240 Specification | |

|---|---|

| Base Size | 332*174*140mm |

| Tray Size | 195*150*26mm |

| Tray load | 1.5kg |

| Applicable size | 5~50mm |

| Tray Option | Material(POM), We can customize to your material requirements |

| Move type | Up, Down, Left, Right, Up-left, Up-right, Down-left, Down-right, Disperse, Compact |

| Communication | Modus TCP, Modbus RTU |

| Adaptive Products | Electronic components, fuses, screws, fasteners, and washers |

| Power Supply | 24V DC |

iF-F380 Flexible Feeder

Feature: Economical and practical

| iF-F380 Specification | |

|---|---|

| Base Size | 491*300*263.5mm |

| Tray Size | 327*256*53mm |

| Tray load | 2kg |

| Applicable size | 15~80mm |

| Tray Option | Material(POM), We can customize to your material requirements |

| Move type | Up, Down, Left, Right, Up-left, Up-right, Down-left, Down-right, Disperse, Compact |

| Communication | Modus TCP, Modbus RTU |

| Adaptive Products | Electronic components, fuses, screws, fasteners, and washers |

| Power Supply | 24V DC |

iF-F530 Flexible Feeder

Feature: Special applications

| iF-F530 Specification | |

|---|---|

| Base Size | 625*412*263.5mm |

| Tray Size | 466*371*53mm |

| Tray load | 2.5kg |

| Applicable size | 30~180mm |

| Hopper volume | 2L |

| Hopper size | 100*203*30mm |

| Move type | up, down, left, right, up-left, up-right, down-left, down-right, disperse, compact |

| Communication | Modus TCP, Modbus RTU |

| Adaptive Products | Gemstones watch parts, and small medical or electronic components |

| Power Supply | 24V DC |

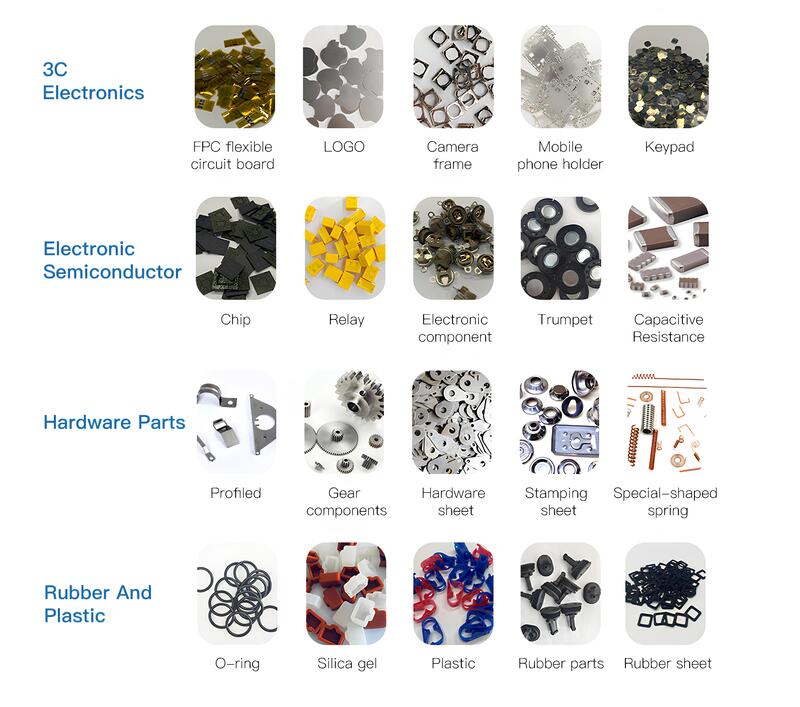

Plates for a Wide Range of Materials

We choose the most suitable material and pallet type for you according to your material and customize it completely according to your requirements FREE of charge.

Supports Multiple Color Customization

We can customize backlighting in a variety of colors, which include but are not limited to white(standard), red, green, yellow, and of course infrared.

Multi-function Debugging Software

The software supports multi-directional movement, amplitude, and frequency can be adjusted according to the material, and through a variety of communication(TCP/IP, Modbus RTU) methods to realize the link with the robot, equipment, and other control software.

Full Size Hopper Can be Customized

We also support a variety of sizes of hopper customization services, which will be based on your actual needs, size, installation location, and other information to customize the service.

Feed port

Handles

Material outlet

Customized 1L, 3L, 5L, 10L, 20L, and other capacities are available.

Core Competencies

iFeedering offers flexible feeding systems to automate production with cost savings compared to manual labor. Each project receives a customized solution of proprietary processes and equipment to ensure all production requirements are met.

Custom Assembly

Automation flexible feeder tailored to specific business/industry needs.

Assembly Automation

Non-standard hardware automation uses flexible feeder technology to produce unique products.

Electronics

Electric power electronics automation uses automation flexible feeder to make custom power electronics products for specific purposes.

Loading Equipment

Flexible feeder is widely used in feeding automation equipments, which has the characteristics of more suitable materials and easy switching.

Healthcare Industry

Flexible feeder for the use of medical materials to avoid abrasion, impact and deformation of the material.

CNC & Injection Molding

Flexible feeder is widely used for loading and unloading applications in the CNC and injection molding industries.

Accurate positioning

Equipped with industrial vision positioning technology, integrated backlight structure (optional), parts can be accurately positioned on the surface of the vibrating plate for gripping, and the material plate can be removed and washed.

Gentle vibration feeding of parts

Based on multi-directional vibration fitting technology, it controls the movement of loose parts in any direction on the surface of the pick-up window, with adjustable vibration amplitude and vibration mode, gently feeding the parts, without cyclic back-and-forth conveying of parts, reducing surface damage to a very low level and without potential jamming.

High reliability and long life

Based on frequency resonance fitting technology, without other mechanical power sources and transmission mechanisms, ensuring high reliability and long life.

Easy to integrate, easy to configure

MS series flexible feeder parameter configuration software, graphic interface, easy to configure, easy to integrate, can be easily integrated in industrial automation equipment in all kinds of mainstream PLC and robot vision system production system.

The Structure of the Flexible Feeder

The flexible vibration plate is mainly composed of a controller, a voice coil motor and an external structure.

Control Board

The core component of the flexible vibration plate, the controller is mainly used to drive the voice coil motor, accept and release external I/O signals, link the upper computer and execute vibration commands.

Voice coil motor

Voice coil motor vibration plate based on voice coil motor technology drive 3 axis automatic parts flexible feeding system, with higher reliability, flexibility and production efficiency; the material plate is made of flexible material, voice coil motor produces up and down linear motion, drive the workpiece forward and backward, left and right, up and down, flip, aggregation, dispersion and other movements.

External Structure

The external structure is made of one-piece casting, the overall quality is reliable and easy to install, stable operation, and small aftershock can easily adapt to the needs of automated feeding.

Voice Coil Motor Flexible Feeding Performance.

- This adaptable feeder can handle 99% of complex feeding problems for parts ranging from 0.1mm to 150mm.

- It assures gentle handling and versatile movement that reduces production cycles.

- The vibrating plate’s backlight ensures highly accurate part identification, while the flexible plate with custom pallets guarantees smooth and consistent positioning.

- Customized trays, such as black trays, FDA-grade, and ESD anti-static materials, augment the feeder’s performance.

- Most importantly, structured trays enable quick replacements, support different vibration modules and easy setup of new vibration solutions that improve flexibility and scalability in production.

Advantages of iFeedering Flexible Feeder

0.2mm or less thin parts feeding, the traditional vibration plate feeding, encounter thin class of easy to stack the film, can not be divided; and our flexible feeder using multi-way vibration to disperse parts, visual photo positioning, robot gripping, a good solution to the thin skin class of parts feeding problem.

the surface is easy to scratch the damage of electroplating products, because the traditional vibration plate in the silo constantly cycle, the surface of its parts are easy to be scratched between the products and the material channel, and our flexible feeder visual material selection, without circular reciprocal feeding, a clean grasp.

shaped workpiece material selection, transmission vibration plate material selection relies on the geometric characteristics of the parts and quality distribution to achieve the selection of parts direction and sorting, when encountering shaped parts, can not be good and efficient sorting selection, and our flexible feeder based on visual selection of parts, the perfect solution to the problem of shaped workpiece feeding material selection.

the product of small quantities of multi-species switching parts feeding, the current automation of a great trend is flexible production, when the customer a production line needs to adapt to a variety of products production, and requires rapid switching even if the parts are only small characteristics of the difference, the traditional vibration disk needs to replace the disk surface, re-commissioning, time-consuming, production is difficult to debug stable; vibration disk frequent card material, and when the variety of parts, the case of more The preservation of different parts of the vibration plate surface is an exceptionally tedious problem, and even debugging and replacement need to seek help from the vibration plate supplier to the scene, and our flexible feeder combined with visual gripping, can store a variety of material selection procedures, a minute to switch between product types of production, to meet the current flexible small batch multi-species automation needs.

Advantages of Flexible Feeding Tray

Based on the personalized structure of the customer’s product shape, we structure the design of the material tray (holes, slots, teeth, drawing, etc.), this design can make the parts quickly and accurately be positioned to identify the gripping, reducing the waiting time for photos and greatly improving production efficiency

Highly versatile

Applicable to a variety of small parts, complex geometric shapes, surface plating afraid of scratching, thin sheet type, shaped parts.

Flexible production

Can realize multi-species sharing and fast material switching

Low noise

No abrasion: no circular vibration of materials, no abrasion of materials, low noise, and no risk of material jamming.

Precise positioning

Independently developed industrial vision positioning technology, which can precisely position the grasping, and the image positioning accuracy can reach ±0.05mm.

How to Choose a Flexible Feeder Manufacturer?

Understand the industry, and distinguish the application.

Understand the emerging areas such as parts finishing machine and flexible vibration tray, flexible vibration tray as a vibration tray and parts finishing machine to supplement, mainly to solve the products that can not be orderly finishing, through the robot plus vision for screening and feeding, not high efficiency, larger investment, but the advantage is that it can solve the problem of unattended.

According to the process, narrow down the range

Flexible feeder as a kind of automatic feeding equipment, need to fully understand their own product characteristics and process requirements and choose a suitable feeding method, only then you can narrow the search, and find a suitable for their own vibrating plate manufacturer to do twice the work with half the effort.

How to choose the right size flexible feeder?

The size of a flexible feeder is mainly determined by the material, efficiency, and beat rate.

- Select the appropriate flexible feeder model by confirming the tray size based on the dimensions of the material.

- The probability of accurately positioning materials in the desired location on the vibration plate improves with its size; larger plates enhance the success rate of material positioning.

- Consider the overall production rhythm of the equipment. Higher production rates necessitate larger discs, which in turn more effectively identify materials.

What Kind of Material is Suitable for Flexible Feeder?

Optimizing Part Handling: Adapting to Shape, Precision, Surface Sensitivity, and Separation Challenges with Advanced Feeding Solutions.

Shaped Parts

Traditional vibratory plates often struggle with parts having irregular structures, leading to instability and uncertainty in the loading process. The main challenge lies in handling the unpredictability associated with irregularly shaped parts.

High Precision Parts

Feeding high precision parts requires extra care to prevent damage. Traditional vibratory plates often cause parts to pile up, leading to collisions and extrusion. This can result in significant harm to delicate parts, highlighting the need for a more protective feeding approach.

Surface-Sensitive Parts

Parts that are prone to surface scratching demand a frictionless feeding process. The flexible feeder is designed to protect such parts from scratches caused by friction, ensuring their surface integrity remains unscathed throughout the feeding process.

Parts Not Easy to Separate

Parts that tend to stack and cling together pose a challenge for traditional vibratory plates, which struggle to separate them effectively. The flexible feeder, with its adjustable vibration frequency, excels in gently and efficiently separating these parts while maintaining their integrity.