Industrial robotics has come a long way from its humble beginnings. Over the years, robotics technology has been used in a variety of industries, ranging from automotive to consumer electronics.

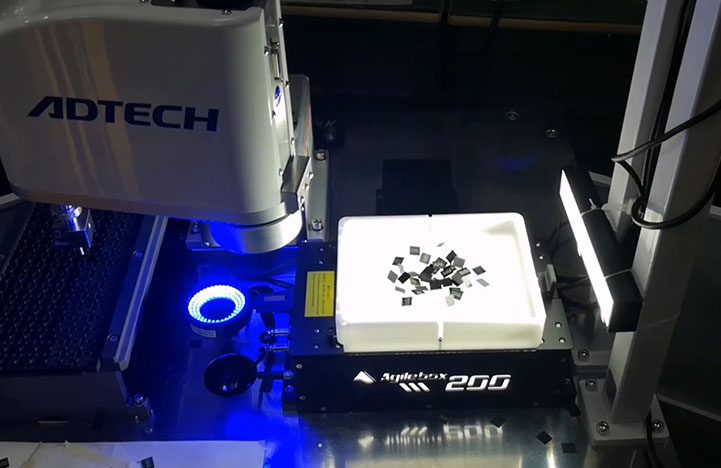

While much of the focus in robotics technology has been on the development of the robots themselves, there has been an increased emphasis on the development of the systems that support the robots. This includes the development of flexible feeder systems, which play an important role in the automation of industrial processes.

In this article, we will explore the role of flexible feeder systems in industrial robotics, as well as some of the benefits and challenges associated with their use.

What are Flexible Feeder Systems?

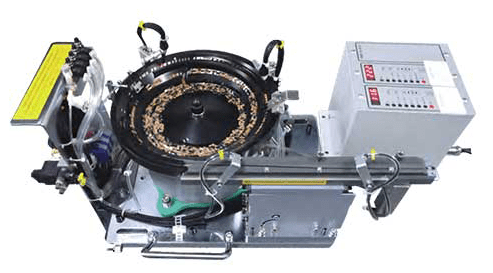

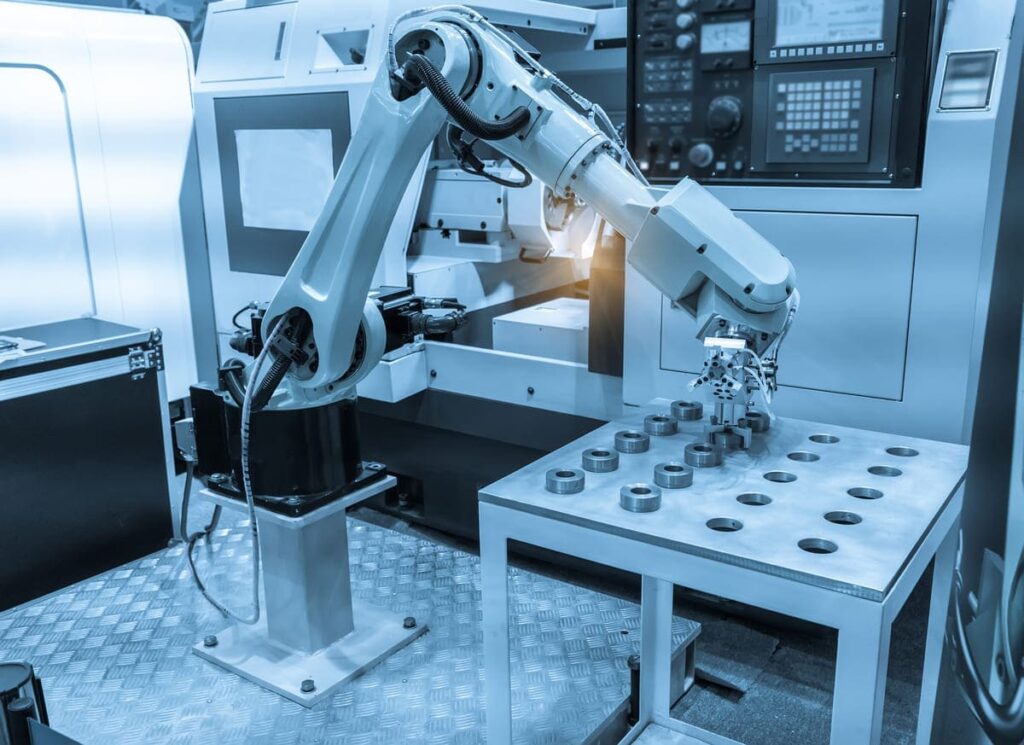

Flexible feeder systems are an important component of industrial automation. They are used to move materials from one place to another within the manufacturing process.

Flexible feeder systems can be used to move a variety of materials, including nuts and bolts, screws, washers, and other small parts. The systems are designed to be flexible in order to accommodate different types of materials, sizes, and shapes.

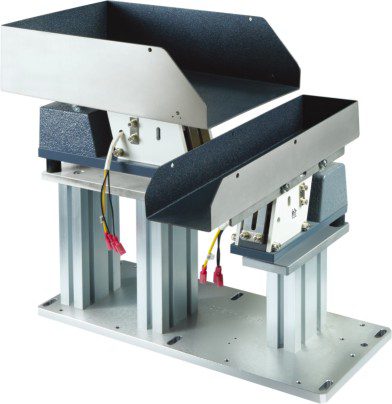

Flexible feeder systems can be divided into two types: static feeders and dynamic feeders. Static feeders are designed to move materials in a linear fashion, while dynamic feeders are designed to move materials in a more complex fashion.

Dynamic feeders are typically used in applications where there is a need for more precise control over the movement of the materials.

Benefits of Flexible Feeder Systems in Robotics

One of the primary benefits of using flexible feeder systems in industrial automation is that they help to reduce manufacturing costs. By automating the process of moving materials, the cost of labor is significantly reduced. Additionally, the use of flexible feeder systems can help to reduce the amount of time it takes to complete a process.

This can help to increase production efficiency and reduce the amount of time it takes to complete a given task.

Another benefit of using flexible feeder systems in robotics is that they can be easily customized for different applications. This allows for greater flexibility in the manufacturing process, as different materials and shapes can be handled with ease.

Additionally, the feeder systems can be programmed to handle different speeds and sizes, allowing for greater control over the process.

Finally, the use of flexible feeder systems in robotics can help to improve safety in the workplace. By automating the process of moving materials, the risk of injury is reduced, as there is no need for humans to be in close proximity to the moving parts.

Additionally, the use of flexible feeder systems can reduce the amount of noise generated in the workplace, as the motors used to power the systems are typically much quieter than those used in manual operations.

Challenges of Flexible Feeder Systems in Robotics

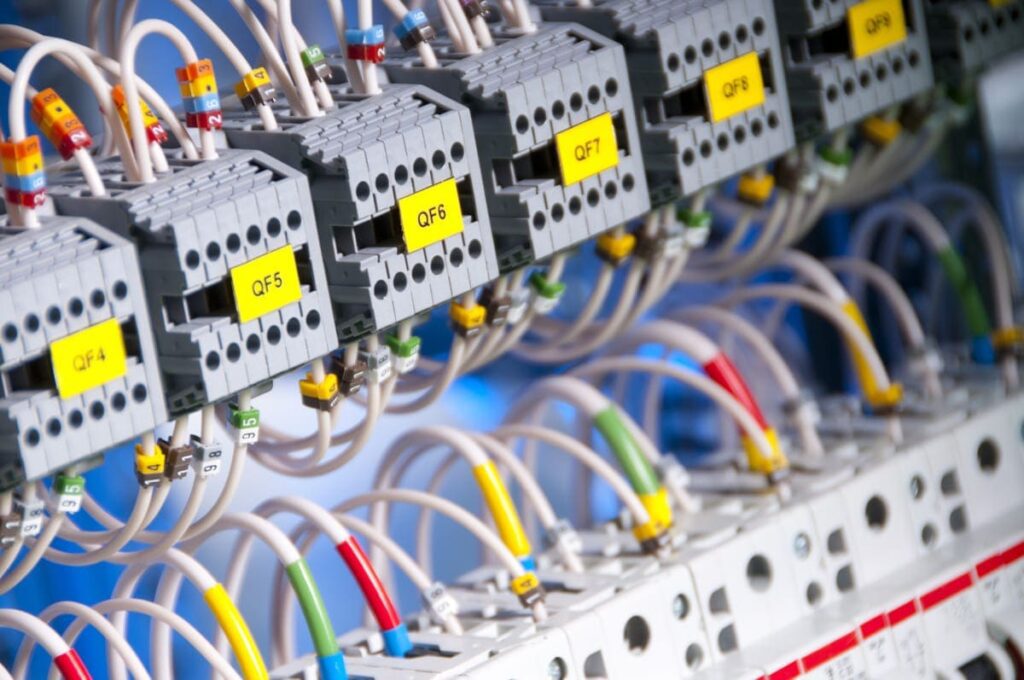

While flexible feeder systems can offer a number of benefits in industrial automation, there are also some challenges associated with their use. One of the primary challenges is that the systems can be costly to purchase and maintain.

Additionally, the systems can be complex to program and require a significant amount of time and effort to set up and maintain.

Another challenge associated with the use of flexible feeder systems is that they require a significant amount of space in order to be used effectively. This can be a challenge in some manufacturing environments, as space is often limited.

Additionally, the systems can be difficult to maintain, as the moving parts can be prone to wear and tear over time.

Finally, the use of flexible feeder systems can also be challenging from a safety perspective. As the systems are automated, there is a risk that the materials being moved could be mishandled, leading to potential injury or damage.

Additionally, the systems can be prone to faults, which can lead to further safety issues.

FAQs

Q: What are the benefits of using flexible feeder systems in industrial robotics?

A: The benefits of using flexible feeder systems in industrial robotics include reducing manufacturing costs, increasing production efficiency, providing greater flexibility in the manufacturing process, and improving safety in the workplace.

Q: What are the challenges associated with the use of flexible feeder systems in robotics?

A: The challenges associated with the use of flexible feeder systems in robotics include the high cost of purchase and maintenance, the need for a significant amount of space, and the potential for safety issues due to faults or mishandling of materials.

Q: What types of flexible feeder systems are available?

A: There are two types of flexible feeder systems available: static feeders and dynamic feeders. Static feeders are designed to move materials in a linear fashion, while dynamic feeders are designed to move materials in a more complex fashion.

Conclusion

Flexible feeder systems play an important role in the automation of industrial processes. The systems are used to move materials from one place to another within the manufacturing process, and can be customized for different applications. The use of flexible feeder systems can offer a number of benefits, including reduced manufacturing costs, increased production efficiency, and improved safety in the workplace. However, there are also some challenges associated with the use of flexible feeder systems, including the high cost of purchase and maintenance, the need for a significant amount of space, and the potential for safety issues due to faults or mishandling of materials.