Introduction:

Choosing the right flexible feeder for your manufacturing process can be a daunting task. There are many factors to consider, such as the type and size of parts you need to handle, the required speed and accuracy, and the budget.

In this article, we will guide you through the process of selecting the right flexible feeder for your application.

Identify Your Needs:

The first step in choosing the right flexible feeder is to identify your needs. What types of parts do you need to handle? What are the sizes and shapes of these parts?

Do they have any special requirements, such as delicate handling or precise orientation? How many parts do you need to handle per minute or hour?

Answering these questions will help you narrow down your options and choose a feeder that meets your specific needs.

Consider the Type of Feeder:

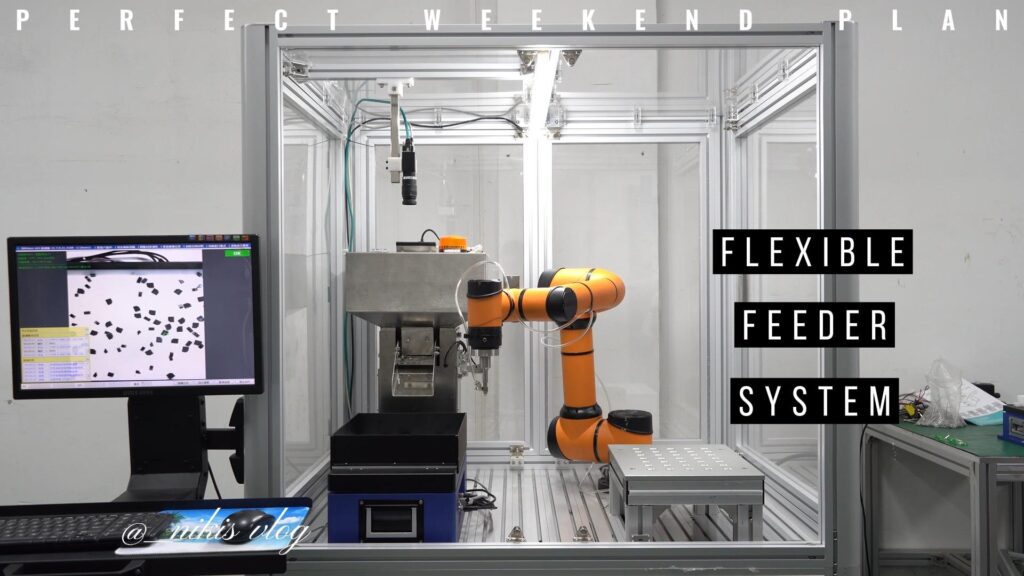

There are several types of flexible feeders available, each with its own advantages and disadvantages. The most common types are vibratory feeders, centrifugal feeders, and vision-guided feeders.

Vibratory feeders use vibration to sort and orient parts, while centrifugal feeders use centrifugal force.

Vision-guided feeders use cameras and sensors to detect and sort parts. Consider which type of feeder is best suited for your application.

Evaluate Speed and Accuracy:

Speed and accuracy are critical factors in selecting a flexible feeder. The speed of the feeder should match the production rate of your assembly line.

The accuracy of the feeder is determined by its ability to correctly sort and orient parts. The higher the accuracy, the lower the chance of errors or defects.

Consider the required speed and accuracy for your application and choose a feeder that meets those requirements.

Assess Flexibility and Customization:

Flexibility and customization are important factors to consider when choosing a flexible feeder. A flexible feeder should be able to handle a wide range of parts, shapes, and sizes.

It should also be customizable to fit your specific needs. Look for a feeder that allows for easy adjustments and customization, such as changing the bowl size or adjusting the sorting mechanism.

Evaluate the Cost:

The cost of a flexible feeder is an important consideration, as it can vary greatly depending on the type and complexity of the feeder.

Consider the cost of the feeder in relation to the benefits it provides, such as increased efficiency and reduced labor costs.

Choose a feeder that fits within your budget but also provides the necessary features and benefits.

FAQs:

Q: How much does a flexible feeder cost?

A: The cost of a flexible feeder varies depending on the type, size, and complexity of the feeder. A basic vibratory feeder can cost a few thousand dollars, while a more complex vision-guided feeder can cost tens of thousands of dollars.

Q: How do I know if a feeder can handle my parts?

A: Check the specifications of the feeder to ensure that it can handle the sizes and shapes of your parts. You can also request a sample test to confirm its capability.

Q: How do I maintain a flexible feeder?

A: Regular cleaning and maintenance are required to keep a feeder running smoothly. Follow the manufacturer’s guidelines for maintenance and cleaning.

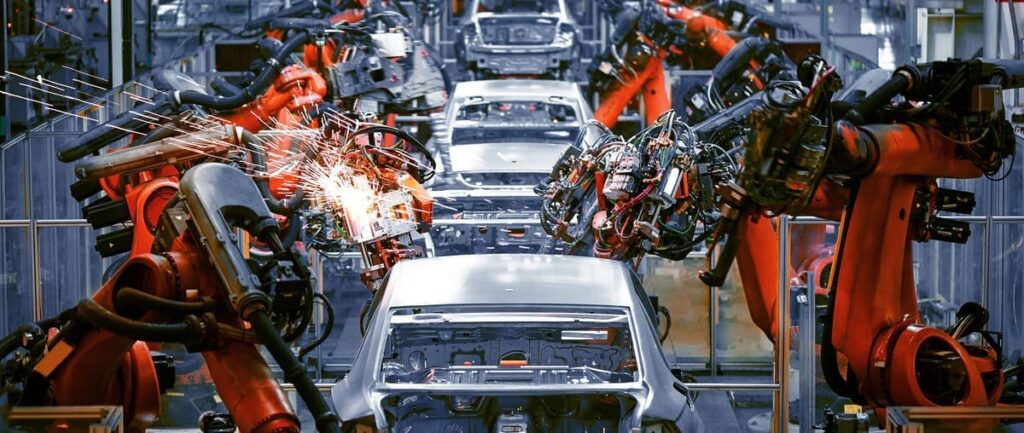

Q: Can a flexible feeder be integrated with other automation equipment?

A: Yes, flexible feeders can be integrated with other automation equipment such as robots, pick and place systems, and assembly machines.

Q: How long does it take to set up and install a flexible feeder?

A: The setup and installation time of a flexible feeder depend on the type and complexity of the feeder. A basic vibratory feeder can be set up in a few hours, while a more complex vision-guided feeder may take several days.

Conclusion:

Choosing the right flexible feeder for your application is crucial to achieving efficient and accurate production.